3D printing ‘glue gun’ heals fractures by printing living bone in real time

Portable 3D bone printer creates biodegradable implants during surgery, promoting faster, infection-free bone healing.

Edited By: Joseph Shavit

Edited By: Joseph Shavit

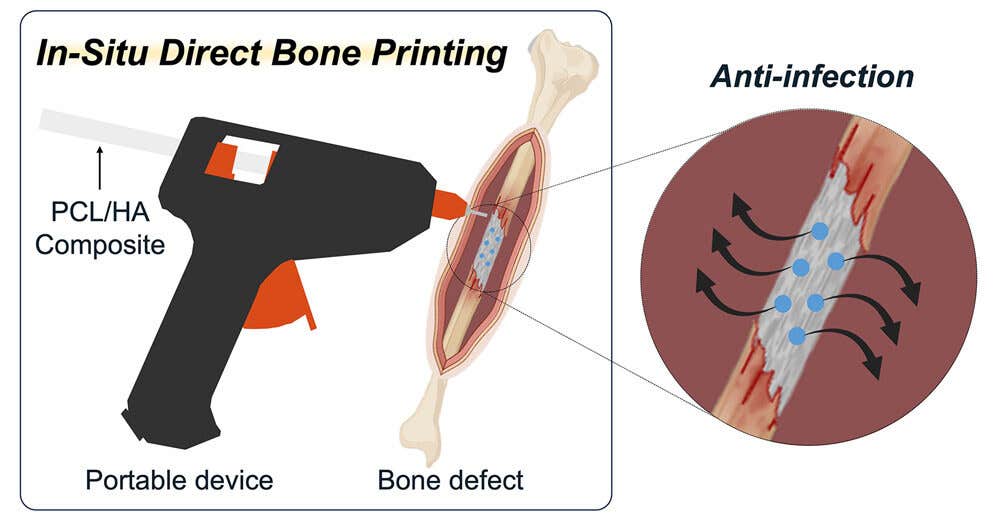

Graphical abstract: A portable device for in situ printing of bone scaffolds. (CREDIT: Cell: Device)

During a complicated bone surgery, every second matters. The longer a wound is open, the more likely it is to become infected and injured. Now picture this: Surgeons can now print a new piece of bone directly into the patient’s body, right in the operating room. This once distant dream is becoming more of a reality with a handheld 3D bone printer, similar to a glue gun, but prints living bone scaffolds instead of glue.

Researchers have created a small bone 3D printing tool, which allows a doctor to "draw" biodegradable implants directly onto a fracture or defect during surgery. This advancement is detailed in the journal Device and written by a team led by biomedical engineer Jung Seung Lee at Sungkyunkwan University.

How the handheld Bone Printer Works

A key feature of the new tool is its simplicity. Known as a hot-melt extrusion, the device heats and extrudes a mixture of polycaprolactone (PCL) and hydroxyapatite (HA), which can more closely mimic both the strength and structure of human bone. PCL is a soft and flexible biodegradable polymer that melts at low temperatures, so it can also conform to the complex shapes of bone. HA is the same mineral that makes up over half of a real bone, which will facilitate hardness and support the growth of new bone cells.

The researchers were able to develop PCL/HA rods that melt at about 80 degrees Celsius, a high enough temperature to create sturdy, load-bearing structures, and low enough to prevent damage to surrounding tissue. Surgeons can manually control the nozzle, molding the bone graft in real time so it fits precisely into the defect without a pre-formed mold or preparation time.

“Because the device is small and manually controlled, the surgeon is able to change the printing direction, angle, and depth during the procedure in real time,” Lee said. “The entire procedure is done in minutes, thus decreasing operative time and improving efficiency.”

A Safer, Cleaner Way to Heal Bone

Classic bone repair implants relied on metal materials, donor tissue, or 3D printed pieces that were pre-formed so they could be placed in the defect. These materials are unable to accommodate every irregular break or uneven curvature, and additionally require the use of solvents or chemicals in the process that may reside in the body. There are no concerns for either of these issues with the handheld system since it prints directly inside the body without residual waste, making it a cleaner and quicker option.

Tests showed the appropriate composite blend, which is the 50H formulation, was about a 25 percent HA. Higher percentages increased brittleness and clogged the nozzle. The engineered composite was a durable material that could withstand more than 100,000 compressive cycles, which is equivalent to several weeks' worth of walking or movement. Unlike do-it-yourself cement fillers that do not change locations, the printed scaffolds are degraded and absorbed by the patient’s bone.

Combating Infection While Promoting Growth

Bone surgeries have a well-known risk of developing postoperative infections, which increases with the implantation of foreign materials. In order to address infection, Lee's group embedded two common antibiotics, vancomycin and gentamicin, within the PCL/HA filament. When the scaffold is printed, it slowly spills vancomycin and gentamicin and bathes the injury site in infection-fighting agents over the course of many weeks.

"This localized delivery strategy provides significant clinical advantages compared to delivering antibiotics systemically, as it may reduce side effects and reduce the development of antibiotic resistance," Lee emphasized.

In addition to combating infection, the biomaterial itself stimulates new bone growth. In vitro studies have shown that when stem cells are cultured on the scaffolds, they deposit calcium faster and express elevated levels of important osteogenic genes, including osteopontin and collagen type 1 alpha 2.

Pre-osteoblast cells, the most primitive form of bone cells, also demonstrated robust growth on the material, and the scaffolds kept these cells proliferating over time. These observations suggest that the printed scaffolds serve not only to provide physical support, but also biological support for healing.

Testing in Living Tissue

In order to see how the device would perform in situ, the researchers tested the device on rabbits with a full femoral fracture. They printed the biodegradable scaffolds directly into a one-centimeter gap in the bone and compared the results to traditional bone glue. At the end of the 12-week healing period, the rabbits treated with the printed material showed no signs of infection or necrotic tissue. Instead, bone healing had commenced.

Microscopic examination exhibited dense collagen networks and organized bone matrices near the area of the printed scaffold, demonstrating that the implant's integration was, in fact, natural tissue integration.

Micro-CT imaging established that the scaffold experienced the formation of more complex-informed bone that possessed greater surface area and superior mechanical properties than the control cement. These advancements reinforce the notion that the printed material could restore function more effectively and safely.

Future of Personalized Bone Repair

The versatility gained through this system points towards the ability for a fully customized experience for bone repair in the future. By adjusting the ratio of PCL to HA, physicians will be able to manipulate the hardness and degradation of the implant.

This could lead to the ability for surgeons to design scaffolds for delicate facial bones or large load-bearing segments. Furthermore, the PTC chip that was included inside the printer will add accuracy surrounding thermal control during the process and prevent the loss of nearby living tissue.

Although the research is still in animal studies, the research team is ready for human trials; however, it must still meet the demands of manufacturing requirements and sterilization protocols prior to getting into hospitals. If successful, this technology could be a new option for surgeons to utilize in repairing trauma injuries, congenital bone defects, and even complex fractures requiring multiple surgeries.

Research's Practical Applications

This portable 3D bone printer could reshape the future of orthopedic care. Rather than using an implant previously designed by other companies, bone grafts could be created for specific patients in mere minutes. Reducing time in surgery, reducing infection risk, while naturally healing the patient.

Furthermore, with the ability to administer antibiotics during the surgeries, the need for systemic antibiotics can be reduced, thereby decreasing resistance and side effects. All of this means quicker recovery for patients, fewer complications, and ultimately less time in the hospital.

From the research perspective, the use of this novel approach opens new doors for regenerative medicine, personalized surgery, and a bridge between engineering and healing.

Research findings are available online in the journal Cell: Device.

Related Stories

- New light-activated injectable gel heals bone faster and safer

- A patient's blood could regenerate their broken bones, study finds

- Revolutionary biomaterial can regenerate bone and teeth, study finds

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Writer and Editor

Joshua Shavit is a Nor Cal-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a co-founder of The Brighter Side of News, he focuses on positive and transformative advancements in technology, physics, engineering, robotics and astronomy. Joshua's work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.