Flexible nylon film generates electricity from compression

A tough nylon-11 film makes electricity when squeezed and still works after car-level compression and thousands of cycles.

Edited By: Joseph Shavit

Edited By: Joseph Shavit

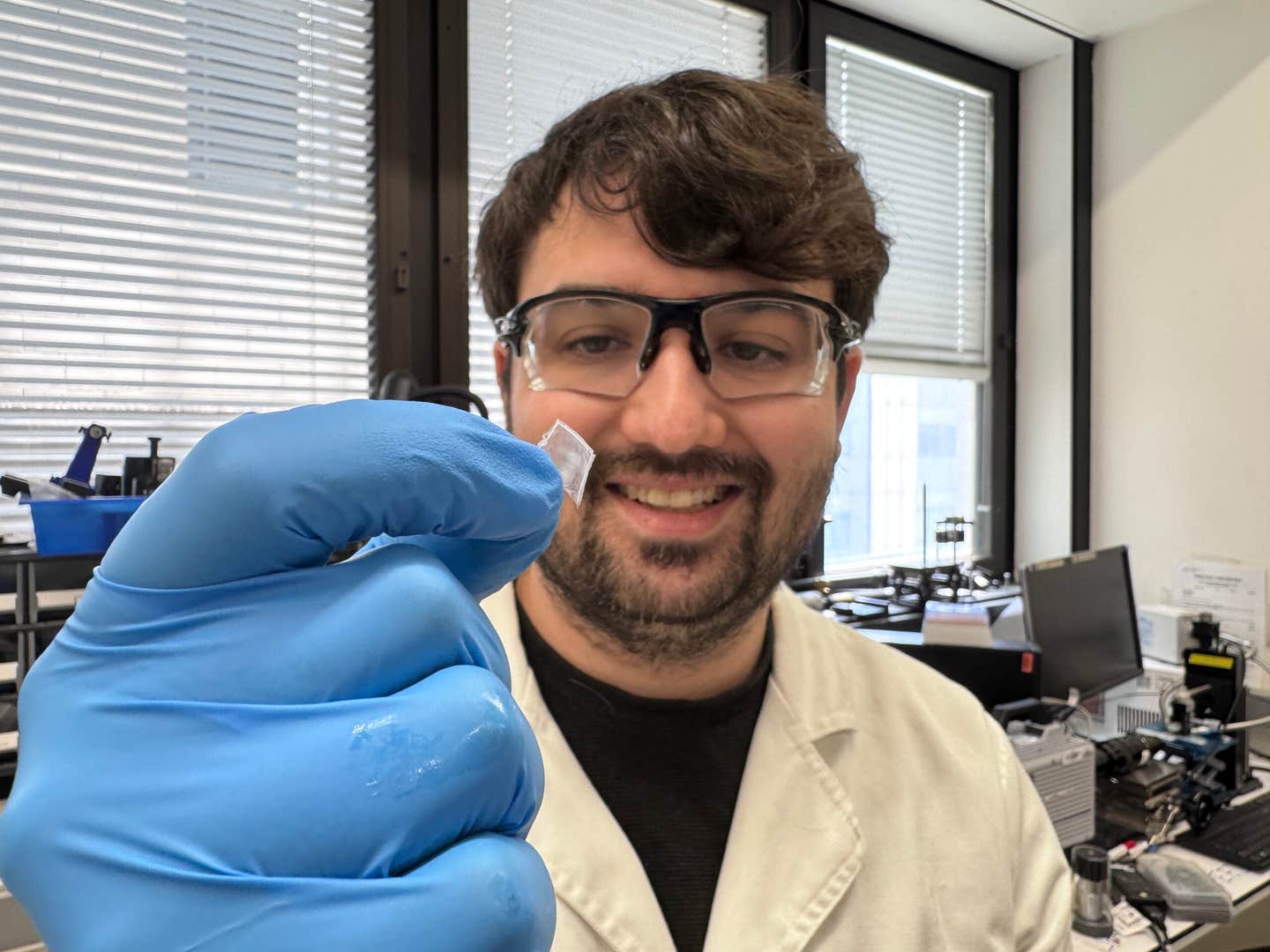

PhD researcher Robert Komljenovic holds the tough and flexible nylon film developed at RMIT University that generates electricity when bent, pressed or compressed. (CREDIT: Will Wright, RMIT University)

A thin sheet of nylon does not look like much on its own. But in lab tests, a film made by researchers at RMIT University kept generating electricity after being folded, stretched, and even run over by a car, again and again.

That kind of toughness matters because the basic trick the film uses is simple: squeeze it, and it produces an electric charge. Materials that do this are called piezoelectric, from the Greek word for “to press.” Quartz, some ceramics, and even bone can behave this way.

Piezoelectric parts already sit inside modern vehicles, including fuel injectors, parking sensors, and airbag systems. The RMIT team’s aim is a flexible alternative that can survive real-world punishment and harvest energy from everyday pressure and motion.

Turning tough nylon into an energy generator

The work is led by Distinguished Professor Leslie Yeo and Dr Amgad Rezk, both from RMIT’s School of Engineering. The first author is RMIT PhD researcher Robert Komljenovic.

The team started with a durable industrial plastic called nylon-11. Nylon is known for resilience and heat resistance, and the research paper notes its use in demanding gear, including aircraft carrier arrestor cables, military equipment, and space suits. Nylon-11 can be piezoelectric “in principle,” the paper says, but its performance has been hard to unlock.

A big reason is that nylon-11 can crystallize into several phases. The paper explains that the phase with the most promising piezoelectric behavior has been difficult to obtain and difficult to organize well, using earlier approaches like stretching or solution processing.

The RMIT method adds two forces at once while the film solidifies: intense mechanical vibration and a strong electric field. The researchers describe doing this using nanometre-amplitude surface reflected bulk waves at 10 MHz on a lithium niobate substrate, while a nylon-11 precursor solution dries under ambient conditions.

Yeo summed up the promise in plain language: “This method could power next-generation devices that need to survive real-world stresses, whether that’s wearable tech, sensors or smart surfaces,” he said.

What the measurements show

The study digs into structure, then follows that structure into performance. Using operando synchrotron grazing-incidence wide-angle X-ray scattering and infrared spectroscopy, the team reports that the process drives long-range crystal ordering, improves hydrogen-bond network ordering, and aligns molecular dipoles, all of which support stronger piezoelectric behavior.

One measure of long-range ordering, Herman’s orientation function, rose to about 0.32 for the electromechanical approach, while the solvent-cast control film showed no preferential long-range order.

Electrical output in compression testing separated the films even more. Under cyclic compression, the electromechanically processed film generated 110 pC of charge, compared with 0.6 pC for a solvent-cast control and 3.7 pC for a film made with mechanical vibration alone.

From those measurements, the team reports a macroscale piezoelectric coefficient d33 of 11.26 ± 0.3 pC N−1 for the electromechanical film. They also report peak-to-peak voltage of about 0.65 V at 4 GΩ for that film, compared with about 0.03 V for the mechanically processed film and about 0.005 V for the solvent-cast control.

In terms of power, the electromechanical films reached a power density of 12.5 μW cm−3, which the paper describes as a 400-fold boost over the mechanically processed film.

The researchers also put guardrails around their own testing. They emphasize an in-contact compressive regime to prevent contact separation, because electrostatic forces can otherwise inflate measured values. When they tested with a 1 mm separation, voltages rose for all films, highlighting how easy it is to accidentally measure more than piezoelectric output.

Surviving a car is not the whole story

Durability is where the material starts to feel less like a lab curiosity. The team reports that the electromechanical film retained function after being tapped by a finger, then compressed under a moving vehicle with a load of about 14,000 N, and then tapped again.

In longer testing, the films maintained a consistent response over 20,000 loading cycles under an in-contact force change of 48 N.

Mechanical measurements point the same direction. Nanoindentation showed a compressive modulus Y3 of 1.99 GPa for the electromechanical film, compared with 0.91 GPa for the solvent-cast control. The paper links the improved strength to a more ordered hydrogen-bonded network, supported by shifts in infrared peaks and other measurements.

Limitations and reality

There are limitations, and the team reports them directly. Performance drops with heat and humidity. In one set of measurements, a d33 value of 11.4 pC N−1 at 25°C and 35% relative humidity fell to 3.55 pC N−1 at 60°C and 1.04 pC N−1 at 80°C. At 25°C, raising humidity to 91% relative humidity reduced d33 to 6.4 pC N−1, with the paper pointing to dipole relaxation and device delamination under humid conditions.

Even so, one number stands out for energy harvesting. The study reports a piezoelectric voltage coefficient g33 of 427 × 10−3 Vm N−1, which it says surpasses values previously reported for piezoelectric polymers.

Rezk framed the approach as industry-friendly: “We’re excited to see where prospective industry partners could take this technology, from flexible electronics to sports equipment,” he said.

Komljenovic focused on the physical reality of the film: “The thin-film devices are so robust, you can fold them, stretch them, even run a car over them, and they keep making power,” he said.

Practical implications of the research

If the method scales the way the team hopes, it could support self-powered sensors in places where changing batteries is a headache. Roads and infrastructure are an obvious target, since they experience constant compression from traffic. The same pressure-to-power behavior could also fit wearables or smart surfaces that get bent and tapped all day.

The paper also positions nylon-11 as a non-fluorinated alternative to PVDF, which it describes as a polyfluorinated alkyl substance and an environmental hazard. That makes the material choice part of the story, not just the processing.

The next step, the researchers say, is scaling up the technology for larger applications and exploring partnerships with industry to bring it to market.

Research findings are available online in the journal Nature Communications.

The original story "Flexible nylon film generates electricity from compression" is published in The Brighter Side of News.

Related Stories

- Scientists transform Styrofoam cups and containers into nylon products

- Scientists generate electricity using Tesla turbine-inspired technology

- New transparent window material could cut building energy loss by 50%

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Rebecca Shavit

Writer

Based in Los Angeles, Rebecca Shavit is a dedicated science and technology journalist who writes for The Brighter Side of News, an online publication committed to highlighting positive and transformative stories from around the world. Her reporting spans a wide range of topics, from cutting-edge medical breakthroughs to historical discoveries and innovations. With a keen ability to translate complex concepts into engaging and accessible stories, she makes science and innovation relatable to a broad audience.