Groundbreaking anti-dust tech paves way for self-cleaning surfaces

Dust is a common fact of life, and it’s more than just a daily nuisance – it can get into machinery and equipment, causing breakdowns.

[Mar. 3, 2023: Nat Levy, University of Texas at Austin]

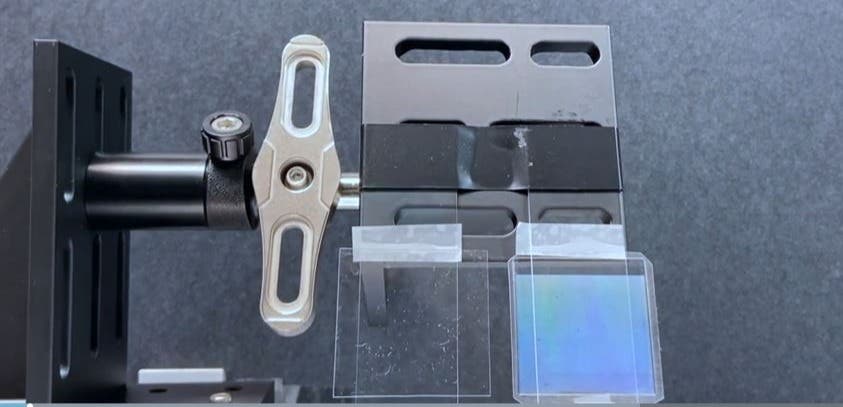

Researchers at The University of Texas at Austin partnered with North Carolina-based company Smart Material Solutions Inc. to develop a new method to keep dust from sticking to surfaces. (CREDIT: The University of Texas at Austin/Smart Material Solutions)

Dust is a common fact of life, and it's more than just a daily nuisance – it can get into machinery and equipment, causing loss of efficiency or breakdowns.

Researchers at The University of Texas at Austin partnered with North Carolina-based company Smart Material Solutions Inc. to develop a new method to keep dust from sticking to surfaces. The result is the ability to make many types of materials dust resistant, from spacecraft to solar panels to household windows.

The research is published in ACS Applied Materials & Interfaces.

"What we've demonstrated here is a surface that can clean itself," said Chih-Hao Chang, an associate professor in the Cockrell School of Engineering's Walker Department of Mechanical Engineering and a lead author of the study. “Particulates aren’t able to stick to the surface, so they come off using just the force of gravity.”

In tests, the researchers piled lunar dust on top of their engineered surfaces and then turned each surface on its side. The result: Only about 2% of the surface remained dusty, compared with more than 35% of a similarly smooth surface.

Related Stories

The researchers said the discovery boils down to things the human eye can't detect. In the experiments, the team altered the geometry of flat surfaces to create a tightly packed nanoscale network of pyramid-shaped structures. These sharp, angular structures make it difficult for the dust particles to stick to the material, instead sticking to one another and rolling off the material via gravity.

These structures provide a passive solution, meaning they don't require any extra energy or materials to remove dust. Compare that with more active solutions such as a car windshield that requires the use of windshield wipers and wiper fluid to clean off dust.

The researchers said the discovery boils down to things the human eye can't detect. In the experiments, the team altered the geometry of flat surfaces to create a tightly packed nanoscale network of pyramid-shaped structures. These sharp, angular structures make it difficult for the dust particles to stick to the material, instead sticking to one another and rolling off the material via gravity.

A nanoscale look at how dust aggregates on this spiky surface. (CREDIT: The University of Texas at Austin/Smart Material Solutions)

These structures provide a passive solution, meaning they don't require any extra energy or materials to remove dust. Compare that with more active solutions such as a car windshield that requires the use of windshield wipers and wiper fluid to clean off dust.

The research was funded via a grant from NASA’s Small Business Innovation Research program, so the first applications focus on space technology. Space dust is especially pesky because of how high-risk everything becomes in that environment, and the conditions make cleaning off dust challenging. Dust wreaked havoc on the Apollo missions and has caused Mars rovers to fail.

"There's not much you can do about lunar dust in space – it sticks to everything and there's no real way to wipe it off or spray it off," said Samuel Lee, a lead author who was an undergraduate researcher in Chang’s group. “Dust on solar panels of Mars rovers can cause them to fail.”

This technology also could have tremendous impact on Earth. It could prevent solar panels from collecting dust and losing efficiency over time. It could protect glass windows and someday even digital screens such as phones and TVs.

Dust accumulation is detrimental to optical elements, electronic devices, and mechanical systems and is a significant problem in space missions and renewable energy deployment. (CREDIT: ACS Publications)

Anti-dust technology has been around for decades, but it has not gained much traction outside of the lab because of scaling challenges. The researchers used fabrication concepts called nanocoining and nanoimprinting, which prints patterns on objects in a modernized version of the way newspapers and photographs were mass produced during the 1800s.

Chang and Lee led the work for UT Austin, along with Stephen Furst, founder and CEO of Smart Material Solutions, which is working to commercial the technology. Other members of the team are Andrew Tunell, Kun-Chieh Chien and Saurav Mohanty of UT Austin; and Lauren Micklow and Nichole Cates of Smart Material Solutions.

Note: Materials provided above by University of Texas at Austin. Content may be edited for style and length.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.

Joseph Shavit

Head Science News Writer | Communicating Innovation & Discovery

Based in Los Angeles, Joseph Shavit is an accomplished science journalist, head science news writer and co-founder at The Brighter Side of News, where he translates cutting-edge discoveries into compelling stories for a broad audience. With a strong background spanning science, business, product management, media leadership, and entrepreneurship, Joseph brings a unique perspective to science communication. His expertise allows him to uncover the intersection of technological advancements and market potential, shedding light on how groundbreaking research evolves into transformative products and industries.