Indian Startup Builds Lightweight Bionic Hand At 1/10 The Cost

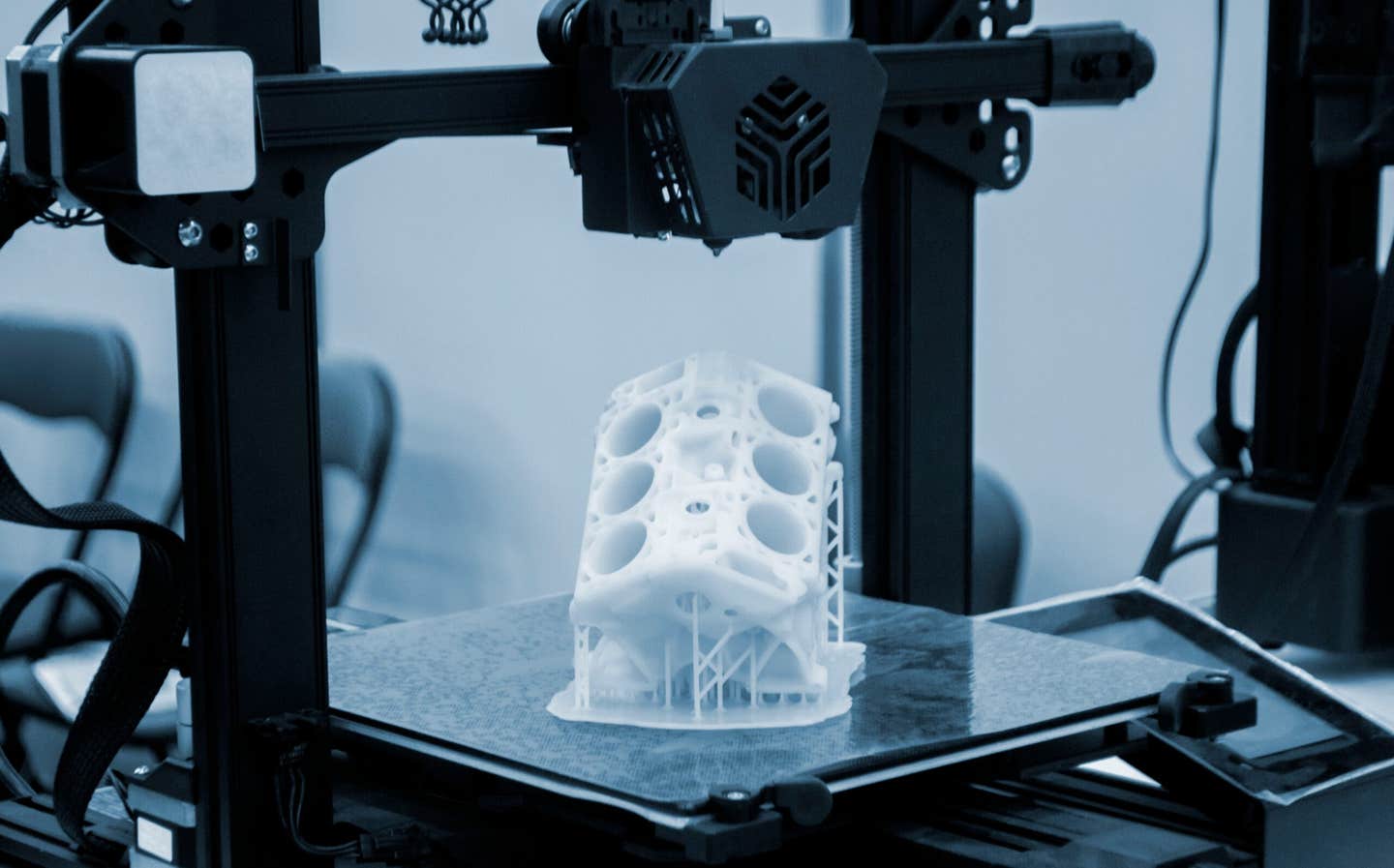

Makers Hive, a Hyderabad-based assistive technology startup, has developed the KalArm, a 3D printed, lightweight and affordable bionic arm

[June 17, 2021: Rinchen Norbu Wangchuk]

Indians with upper limb amputations have found hope in KalArm, a fully functional, 3-D printed, lightweight, EMG-sensor embedded and affordable bionic hand developed by Makers Hive, a Hyderabad-based assistive-technology startup.

Named after Former President of India Dr APJ Abdul Kalam, the device has been designed to address the concerns of millions in need of prosthetic assistance.

The KalArm comes in different palm sizes (small, medium and large) with forearm sockets that vary from one user to another, who are also given the option to customise colours of outset shells/panels. This mobile app-enabled and customisable bionic hand is equipped with a host of impressive features.

Founded in 2018 by Pranav Vempati, Harsha Reddy Ponguleti and Suren Marumamula, Makers Hive was established with an objective to build products that would solve real world problems. Speaking to The Better India, Pranav describes the journey and philosophy behind establishing the startup and developing the KalArm.

He says that while studying Electronics Technology at the Loyola Academy in Hyderabad, he learnt more from collaborating with his peers on projects ranging from robotics to creating an auto-stabilisation gimbals than he did in the confines of a classroom.

That spirit of collaboration was taken to the next level while working for TCS Ignite, an R&D and L&D division of the Tata Group, in Chennai. There, he had the rare opportunity early in his career to work with around 600 employees across 24 different projects related to subjects including drones, robotics, virtual reality and artificial reality.

“Working there early in my career gave me the opportunity to transform ideas into proof-of-concepts and eventually convert those into products,” says Pranav.

While he was in Chennai, one of his mentors was the famous agricultural scientist, M S Swaminathan, the Father of the Green Revolution.

“Spending time with Swaminathan sir brought about a paradigm shift in what I wanted to do. Before meeting him, I harboured ambitions of going abroad, settling down there, earning a fat paycheck, and working on some interesting projects because societies in the West are far more technologically advanced. Swaminathan sir explained the concept of brain drain and inspired me to stay back and work for greater technological advancement back home. The objective behind staying back was to reduce that gap in technological advancement between the West and India,” he recalls.

Researching on what problems he could solve, Pranav found that there was very little product innovation in the healthcare system, especially in the disability space. Making matters worse, the advanced robotics and bionics available for people with disabilities was financially out of reach for most. He wanted to bridge that gap.

Inspiration came from Dr APJ Abdul Kalam and cardiologist Dr B Soma Raju, who developed the famed and affordable ‘Kalam-Raju-Stent’ for coronary heart disease.

“I was also inspired by entities like the Indian Space Research Organisation (ISRO), which are able to perform disruptive innovations while spending only a fraction of what advanced organisations like NASA do. I decided to take up a project where not much innovation has happened in India, but significant progress has been made in the rest of the world. I took up a problem statement like amputations of the hand and wanted to build an affordable solution,” he recalls.

Finding people who share the same vision and passion is probably the hardest part of any startup origin story. Fortunately, Pranav discovered co-founders in Harsha and Suren with complementary skill sets.

Suren comes from a manufacturing background, while Harsha is proficient in matters of sales, strategy and tapping into different revenue streams. Pranav, meanwhile, comes from a background of actually building products, while the company Chief Technology Officer (CTO), Chanakya Gone, looks after their day-to-day operations in terms of product development, compliance, IPs, etc. Today, they’re a team of 20 people with expertise in core engineering, software development, product design and systems architecture, amongst others.

Making it affordable

Most households in developing nations cannot afford advanced prosthetics, particularly those related to the hands because of the high degree of complexity involved in making them. After all, compared to legs, your hands have a lot more functions to perform.

“These advanced prosthetic bionic hands cost as much as Rs 35 lakh to Rs 60 lakh in developed nations. In countries like India, most households cannot afford them. So, I looked into what price points people were already accustomed to here. A single function myoelectric hand would cost Rs 1.5 lakh to Rs 2 lakh in the open market. My objective was to create an advanced bionic hand that would cost close to this amount,” says Pranav.

That was his team’s problem statement. How did they achieve it?

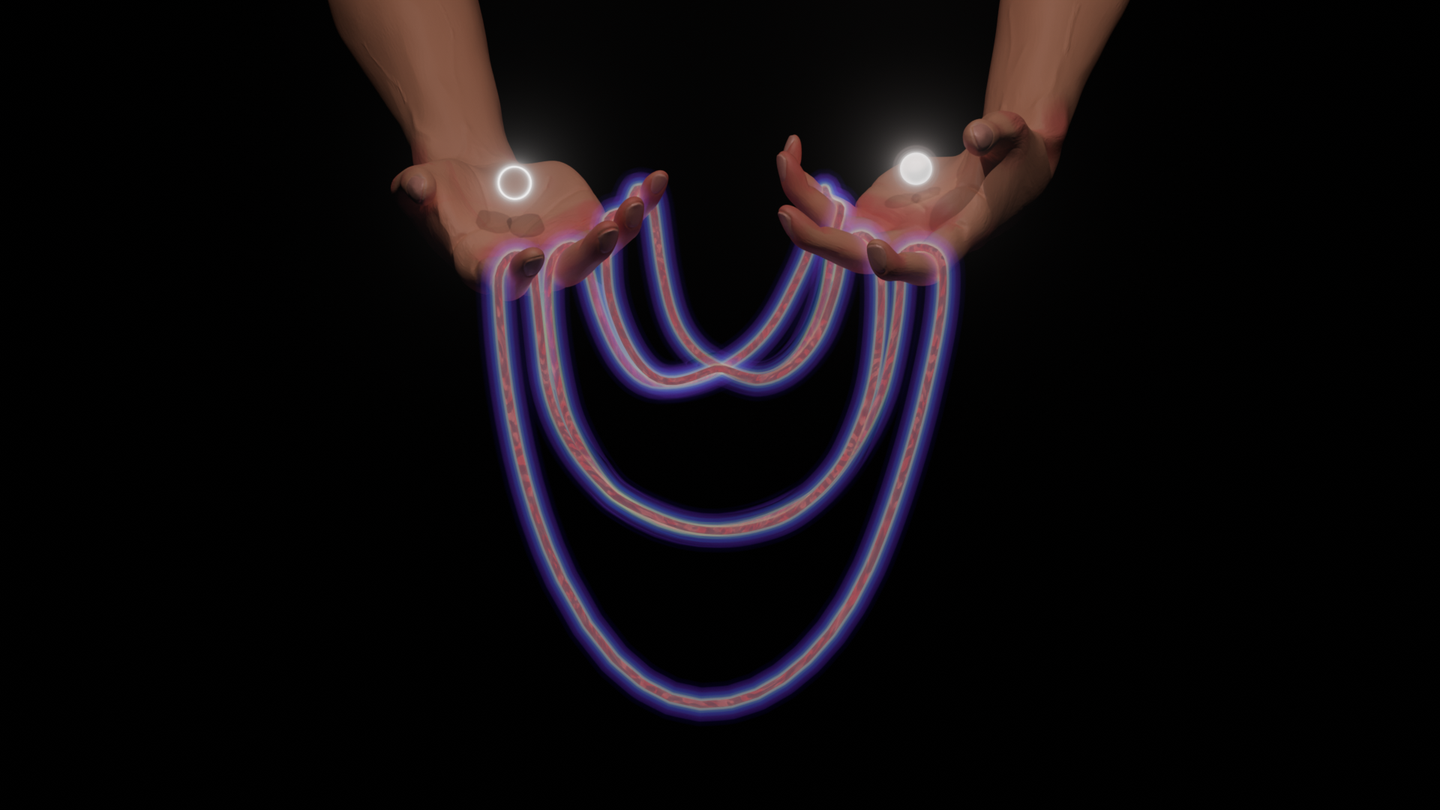

Bionic hands work on something called EMG (electromyography) sensors, which measures small electrical signals generated by your muscles when you move them. When an average human thinks about moving their hands, motor neurons from the brain carry messages to muscles of the hand and forearm.

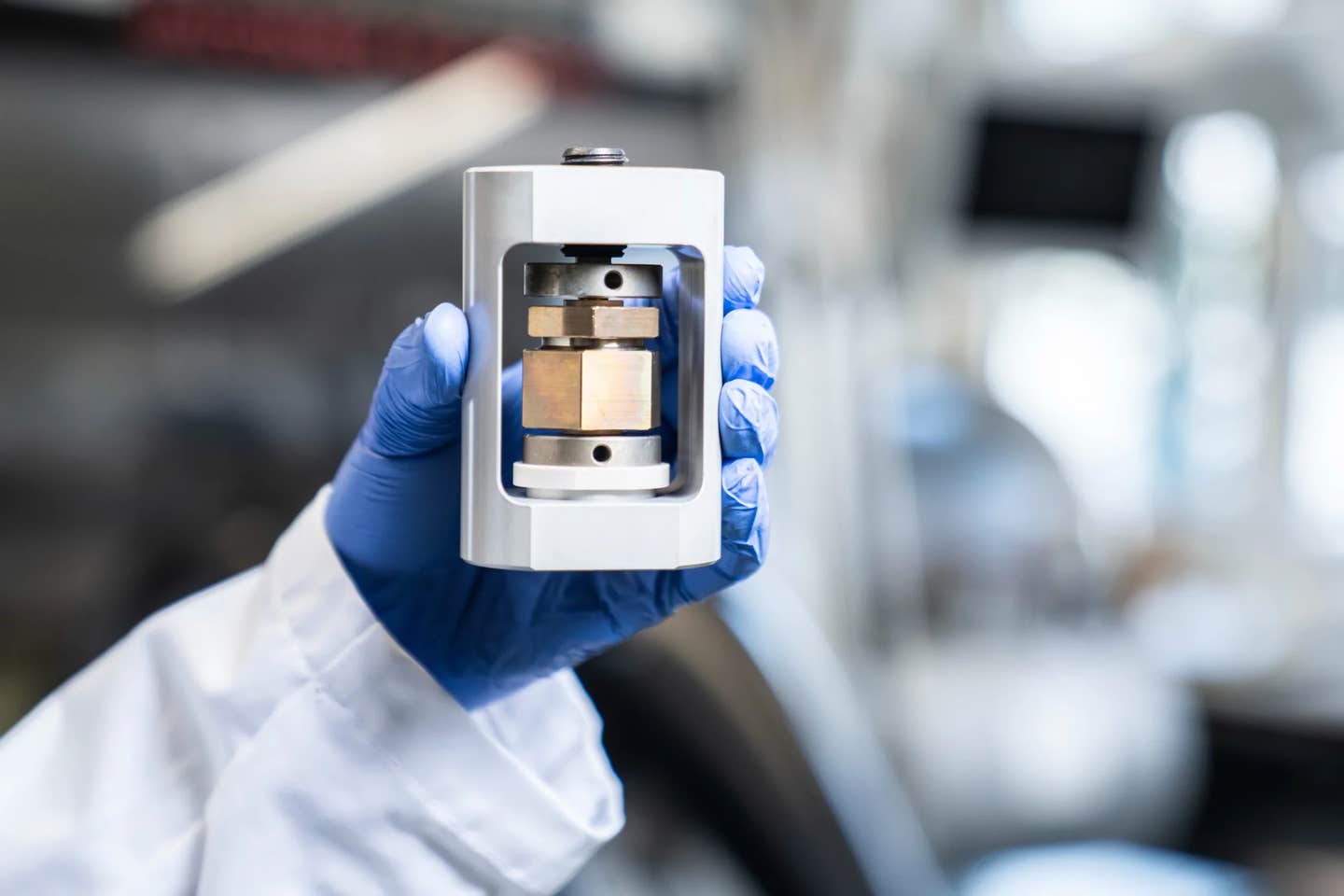

“For amputees who don’t have hands, we have something called flexor and extensor muscles in our forearm. We place a pair of these sensors on these muscles and try to interpret what the person is trying to do. We place a pair of EMG sensors there, which will send instructions to the bionic controller in the wrist area on what kind of functions it needs to perform. Rather than using existing components in the market, we built and tested EMG sensors, bionic controllers, linear actuators inside the hand, thumb mechanism, finger mechanism, wrist mechanism and every other component on our own. We also applied for a lot of IPs in the process. We were able to bring down the price significantly to somewhere between Rs 3.5 lakh and Rs 4 lakh, which is ten times more affordable than any advanced bionic hands with similar features,” explains Pranav.

Of course, not many can afford this amount as well. So for this, Makers Hive is trying to tap into CSR funds. The startup is also in conversation with State and Central governments on getting these bionic hands added to certain schemes so people can avail of government subsidy to buy them.

The KalArm is powered by a 2850 mAh (milliamp Hour) lithium polymer battery which can sustain almost 14 hours of continuous usage. However, the battery is still too bulky for the team’s liking and they’re looking to cut down the size by about 30%, which would bring down the battery life to about 9 hours. The startup will provide an adapter to charge the bionic arm overnight, which can fit in any household socket. Another fascinating feature of the KalArm is the mobile app that Makers Hive have developed to complement its functioning.

“The hand works standalone without the app, but we wanted to build a product which is future-proof. In other words, just like you update your phone with new features, we’ve created an app connected to the bionic hand using bluetooth to send new firmware updates. The app can also be used for performance monitoring. We have created multiple nodes in the bionic hand right from our EMG sensors, battery, bionic controller to the individual actuators. These nodes continuously track the health status of these components and inform the user. Serviceability is a major aspect in a medical device,” he explains.

In the current ecosystem, if there is a problem in any advanced prosthetic hand on the market, users have to take it back to the seller and he/she will further ship it to the main company for repairs. “We can check the health status of the device and its components on the app itself. If these problems can be fixed just by a software update, we send a software patch and the user’s hands will start functioning properly. Only if there are major repairs to be made will the device reach us,” adds Pranav.

The KalArm comes with 18 pre-defined grips (hook grip to hold an object, pinch grip and tripod grip, among others) and 6 custom grips, depending on the user’s specific needs, which they can configure using the app. In rural areas, if people struggle to operate the app, they can approach the seller themselves to configure new grips and add them to the bionic hand.

“I was blown away by the responsiveness of the Makers Hive team when I approached them for their Bionic Hand. While trying it on, I was surprised to see how light the product is. I started to realise that I could do some everyday activities on which I had already lost hope,” says Ravi Bonka, a Hyderabad resident who is currently equipped with KalArm.

Meanwhile, Gayathri, another user, adds, “I’ve been associated with Makers Hive since Day one. We have learnt and evolved everyday. This hand feels great because I always wanted one that would help me carry out a lot of daily tasks. I was waiting for such an arm.”

Testing for global standards

It took the Makers Hive team about two and a half years to develop and test the KalArm. Although it’s a low-risk medical device, they had to ensure it is not merely compliant with Indian medical standards, but can be sold in any part of the world.

“We started testing our components in-house as per US Food and Drug Administration (FDA), the European Union’s Conformitè Europëenne (CE) and other global standards. For example, our bionic hands shouldn’t emit harmful radiation or be affected by radiation from external forces. So, we followed a global standard called IEC 60601, which is a series of technical standards for safety and essential performance of medical electrical equipment published by the International Electrotechnical Commission,” Pranav claims.

For biocompatibility tests on skin sensitivity, irritation or cytotoxicity tests, the startup followed the standard of tests called the ISO 10993. This set entails a series of standards for evaluating the biocompatibility of medical devices to manage biological risk. In this manner, they have also conducted their stress test, load test and other mechanical tests.

“We are currently in the process of finishing our Conformitè Europëenne (CE) certification, which companies need to sell medical devices in the EU. In another six to nine months, we hope to obtain approvals from the US FDA as well. Meanwhile, under the supervision of certified prosthetists, we tested these bionic hands on multiple users from different age-groups, genders, locations (rural or urban), and circumstances in which they lost their arms,” he adds.

Looking ahead

The startup launched KalArm on 3 December 2020 on International Day of People with Disabilities. Although they have received hundreds of pre-orders, setting up their assembly line in Hyderabad has been a cumbersome process thanks to COVID-19. Setting this up is taking time because the founders want to ensure they have all the quality controls and checks in place. While they have a lot of orders today, delivery will only start three months from now.

Meanwhile, they are in the process of concluding their Series A round of funding. Looking ahead, the future looks hopeful, particularly for amputees who can now access this advanced bionic hand.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.

Tags: #New_Innovation, #Robotics, #Prosthetics, #The_Brighter_Side_of_News