New metamaterial bends the rules of physics by combining surprising strength with stretch

A new material inspired by hydrogels defies limits by combining extreme stretch with impressive strength—without breaking under pressure.

Scientists develop double-network metamaterials that are both strong and stretchy, inspired by hydrogels and soft matter design. (CREDIT: Carlos Portela, et al.)

A groundbreaking new material bends the rules of physics by combining surprising strength with impressive stretch. Scientists have long faced a trade-off in materials science: the stiffer something is, the less it can stretch without breaking. But a new kind of synthetic material, known as a double-network metamaterial, could change everything.

Metamaterials are engineered materials with structures at the microscopic level that give them unusual mechanical properties. These structures let the material behave in ways that natural materials can’t. Traditionally, researchers focused on making these materials stiffer and stronger, often ignoring stretchiness or flexibility. But that changed when engineers from MIT began looking to soft, stretchy materials like hydrogels for inspiration.

Learning from Jell-O

Hydrogels are made mostly of water and a small amount of polymer. They’re soft and squishy, but scientists have figured out how to make them tough too. The trick? Combining two very different networks inside the material: one stiff and one soft. When these networks work together, the hydrogel can stretch far without tearing apart.

Researchers wondered: could this same idea work in metamaterials? If you take a stiff, brittle material and structure it with both hard and soft patterns, could you make something that’s both tough and stretchy?

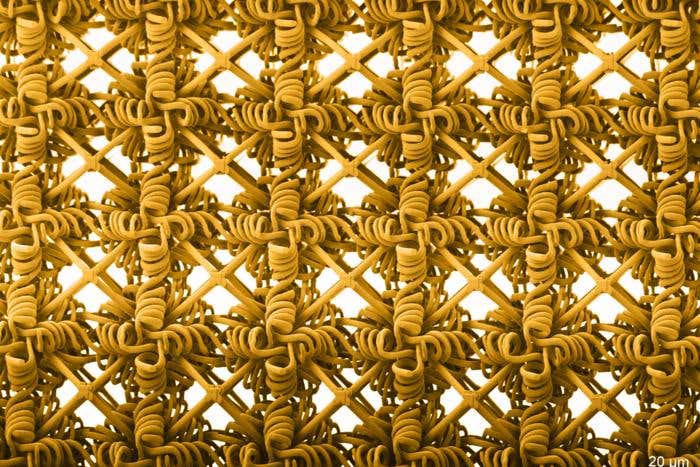

That question led a group of engineers to a creative solution. Instead of choosing a new soft material, they used a single hard one—a plastic similar to plexiglass. What changed was how they shaped it. By designing it with two types of tiny structures—a solid scaffold and a tangled weave—they created a new type of metamaterial that’s not only strong but also stretchy.

A Breakthrough Design

This new material includes two networks: one is a rigid lattice of microscopic trusses and struts, and the other is a flexible weave of coils that wrap around the lattice. Both parts are printed from the same hard plastic using a highly accurate laser printing method called two-photon lithography.

Related Stories

- Invisible material brings a new era of touch screens and wearable devices

- Generative AI designed 5 new battery materials - more powerful and sustainable than lithium

On its own, the plastic is stiff and snaps easily under stress. But when arranged in this double-network design, it behaves in a completely different way. The material can stretch to more than three times its original length without breaking. That’s 10 times more stretch than the same plastic structured as a standard stiff metamaterial.

Carlos Portela, a researcher on the team, explains, “We are opening up this new territory for metamaterials. You could print a double-network metal or ceramic, and you could get a lot of these benefits, in that it would take more energy to break them, and they would be significantly more stretchable.”

How It Works

Think of the soft network as a messy tangle of spaghetti, twisted around the harder structure. As you stretch the material, the stiff parts crack first, but they don’t break cleanly. The tangled soft part holds onto the broken pieces, creating friction and slowing the damage. This tangle spreads the force over more of the material and stops cracks from spreading too fast.

“Think of this woven network as a mess of spaghetti tangled around a lattice,” says Portela. “As we break the monolithic lattice network, those broken parts come along for the ride, and now all this spaghetti gets entangled with the lattice pieces. That promotes more entanglement between woven fibers, which means you have more friction and more energy dissipation.”

It turns out this design doesn’t just stretch—it absorbs energy really well. When you try to pull it apart, the material doesn’t just snap. Instead, it resists by using the friction between the tangled parts to soak up the force. That makes the material much tougher. In fact, lab tests showed that the material could handle three times more stretch and absorb ten times more energy compared to its traditional version made from the same plastic.

Defects That Make It Better

Even more surprising, adding small flaws to the material—something usually avoided in engineering—made it perform better. The team punched holes in the structure and watched what happened.

“You might think this makes the material worse,” says James Utama Surjadi, the lead author. “But we saw once we started adding defects, we doubled the amount of stretch we were able to do, and tripled the amount of energy that we dissipated. That gives us a material that’s both stiff and tough, which is usually a contradiction.”

The defects allowed the material to stretch more evenly, preventing sudden cracks and making failure less likely. Engineers call this “failure delocalization.” Instead of the material snapping at one point, the stress spreads out, and the damage is more controlled.

Big Ideas for Small Structures

To build and test their new metamaterial, the team printed tiny samples just a few millimeters across. These were then placed into a special machine that stretched them slowly while measuring the force. High-speed cameras recorded how the material responded to each pull and tear.

The team also developed a computer model to predict how different patterns and shapes would affect the material’s strength and stretchiness. This tool helps them plan new designs before printing them.

The results are promising. The scientists believe this double-network method could help create stronger, stretchier versions of materials we already use—like glass, ceramics, and even metals. These tougher versions could become the next generation of flexible electronics, wearable sensors, medical implants, or tear-proof clothing.

“We also want to try this approach on more brittle materials, to give them multifunctionality,” says Portela. “So far we’ve talked of mechanical properties, but what if we could also make them conductive, or responsive to temperature?”

By using different materials for each network, researchers could build fabrics that change their shape or stiffness with heat. One example might be a material that becomes softer in warm weather and stiffens in the cold. This could lead to smart fabrics that adapt to their environment, improving comfort and safety in extreme conditions.

A Future That’s Strong and Stretchy

Metamaterials already allow engineers to push past the limits of traditional design. Now, with the help of inspiration from hydrogels and soft matter, these materials are entering a new era.

This research proves that strength and flexibility don’t always have to trade places. By mixing hard and soft structures in the same material, engineers can design metamaterials that work harder, last longer, and adapt more easily to the real world. As these materials grow from tiny lab samples to real-world products, they could reshape how we think about toughness, stretchiness, and strength—all at once.

Research findings are available online in the journal Nature Materials.

Note: The article above provided above by The Brighter Side of News.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.