New project will simulate life on Mars, pave way for NASA’s ‘next giant leap’

As NASA prepares for its “next giant leap”—meaning astronauts on Mars—technology developed by 3D printing construction is paving the way

[August 12, 2021: NASA]

As NASA prepares for its "next giant leap"—meaning astronauts on Mars—technology developed by Austin-based 3D printing construction company Icon is helping pave the way.

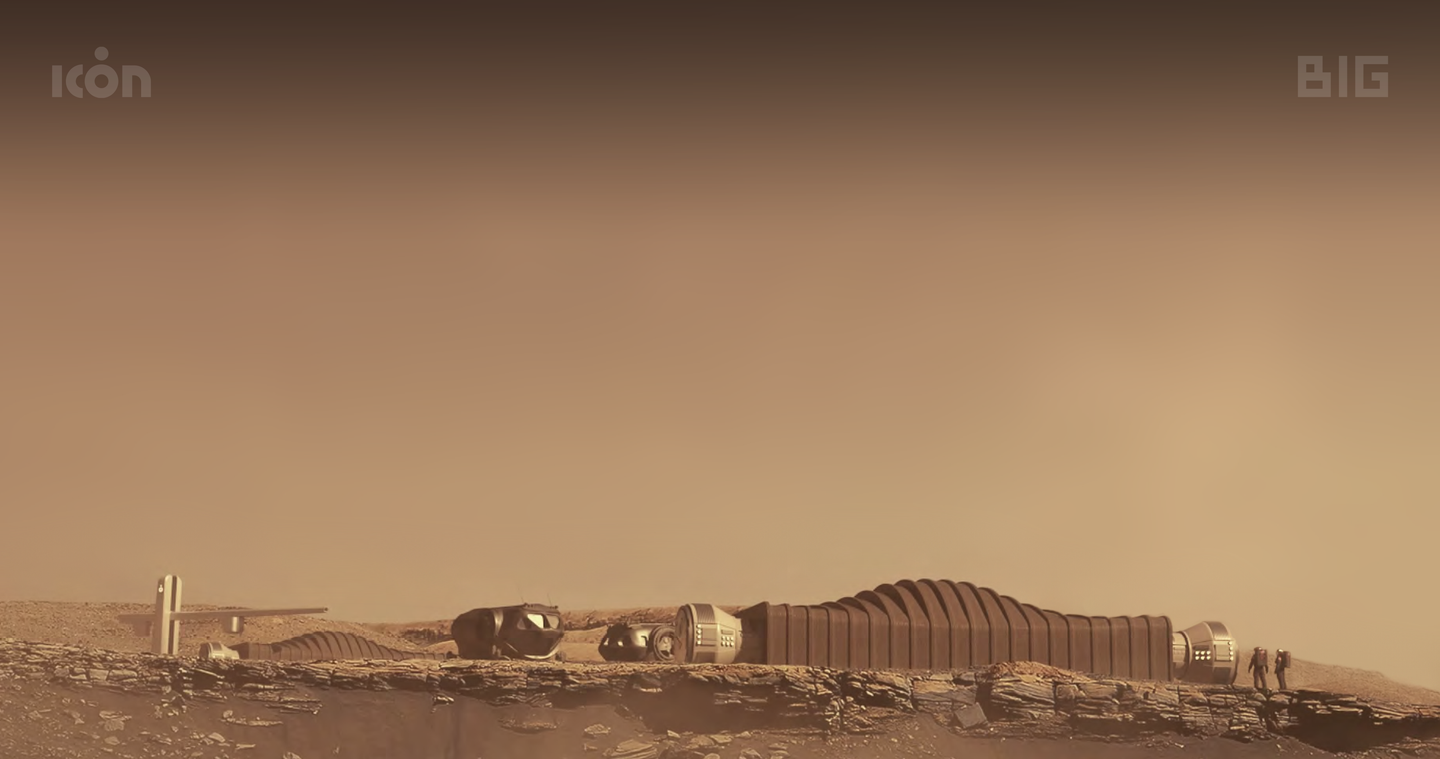

Icon has landed a subcontract with the National Aeronautics and Space Administration, and is teaming with Bjarke Ingels Group, to construct and design a habitation unit that will help the space agency better understand how people may be able to live on Mars in the future.

The company is building a 3D printed structure at NASA's Johnson Space Center in Houston for a series of missions designed to simulate what life could look like for astronauts living on Mars. Once completed, crews will stay in the structure at the Houston space center for one-year stints designed to mimic living conditions on the red planet.

Icon, which printed its first home using 3D technology in 2018, was co-founded by Jason Ballard with the goal of reimagining construction and housebuilding by using novel building techniques to make homes more affordable, resilient and sustainable. The startup has built a number of projects on Earth and has been working to take its technology to new heights by aiming to construct some of the first habitable structures in space.

The Mars simulation project is part of NASA's Crew Health and Performance Exploration Analog, or CHAPEA, designed to mimic life on the surface of Mars to determine what a real mission there would require.

Crews that participate in the simulation will live in a 1,700-square-foot structure, called Mars Dune Alpha, which is being built by Icon's largest printing system, known as Vulcan. Bjarke Ingels Group is partnered on the project and designed the structure.

Ballard said the project is the most realistically simulated habitat ever made by humans.

"We wanted to develop the most faithful analog possible to aid in humanity's dream to expand into the stars. 3D printing the habitat has further illustrated to us that construction-scale 3D printing is an essential part of humanity's toolkit on Earth, and to go to the Moon and Mars to stay," Ballard said.

Once completed, the structure will have four private rooms on one end, work and medical stations on another end, shared living spaces and a food-growing area. Mars Dune Alpha will also feature movable furniture, customizable lighting and temperature and sound controls—all aimed at ensuring that the habitat fits daily routines and circadian rhythms and helps maintain the well-being of the crew.

Bjarke Ingels, founder and creative director of BIG-Bjarke Ingels Group, said data gathered from the project will help inform NASA's standards for long-duration missions and could lay the foundation for future trips to Mars.

"Together with NASA and ICON, we are investigating what humanity's home on another planet will entail from the human experience," Ingel said. "Mars Dune Alpha will take us one step closer to becoming a multi-planetary species."

The first crew of four that will live in Mars Dune Alpha for a year is expected to move in sometime next fall. Additional crews and missions are expected in 2024 and 2025.

NASA said it's looking for participants age 30 to 55 with strong science and technology backgrounds, and applications are being taken through Sept 17.

In announcing the CHAPEA project, NASA said the crew will provide data by conducting simulated spacewalks and participating in activities such as raising crops, preparing meals and performing maintenance and scientific experiments.

Grace Douglas, lead scientist for NASA's Advanced Food Technology research effort at the agency's Johnson Space Center, said in a statement that the crews will play a historic role and test solutions to help NASA meet the complex needs of living on the Martian surface.

"NASA has been exploring Mars—robotically—for more than fifty years. Now, a human trip to the red planet is on the horizon for the first time ever," Douglas said. "Simulations on Earth will help us understand and counter the physical and mental challenges astronauts will face—before they go."

The agency said the habitat will be designed to be as similar to Mars as possible and could include environmental stressors such as isolation, equipment failure, significant workloads and limited resources.

Melodie Yashar, director of architecture and building performance at Icon, said the habitat will primarily provide research on interior space, crew health and food systems. But actual construction on Mars will still come with substantial difficulties, she said.

"While Mars is more hospitable in its environment compared to the Moon, the journey to Mars is very long (roughly 6-8 months one way) and involves countless risks (such as communication blackouts and no evacuation capabilities) that make the task of building autonomously with robots much more challenging," Yashar said.

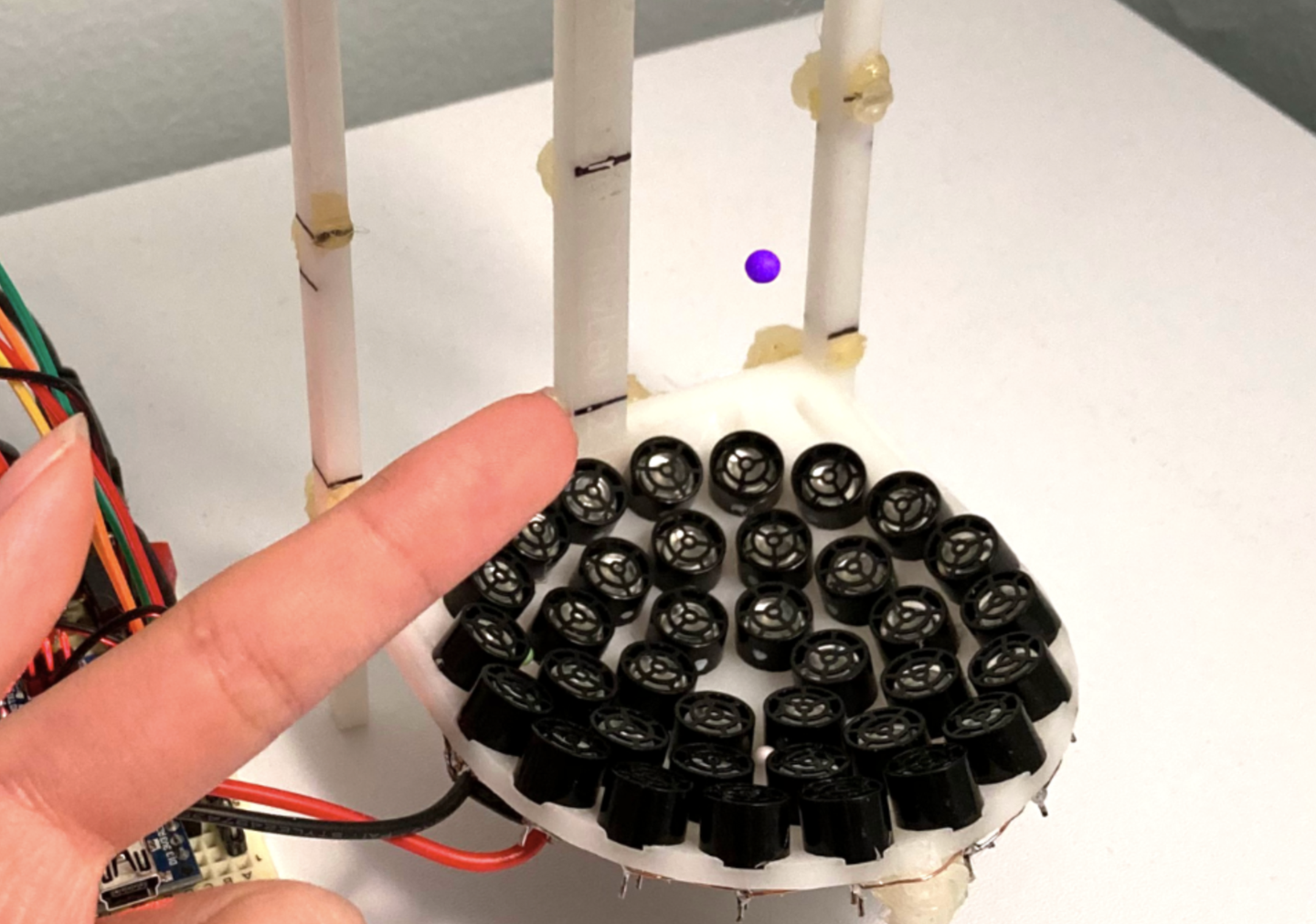

Icon has been aiming its technology at space for some time. In October, it announced a contract with NASA to develop a space-based construction system to create structures intended to help future astronauts explore, live and work directly on the lunar surface, and eventually on Mars.

The technology works similarly to the printers used on Earth, Icon has said, and it aims to use existing materials on the moon to lower shipping costs and account for the harsh environment.

Icon first demonstrated the lunar technology in NASA's 3D Printed Habitat Challenge in 2018. The technology comes as NASA works to launch its Artemis program, which aims to land a man and a woman on the moon by 2024.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.

Tags: #New_Innovations, #Mars, #Space_Travel, #NASA, #3D_Printing, #The_Brighter_Side_of_News