Programmable hydrogel ‘smart skin’ can hide images, shift texture, and morph shape

A hydrogel film can look blank, then reveal a hidden image after a solvent wash or temperature change, no ink required.

Edited By: Joseph Shavit

Edited By: Joseph Shavit

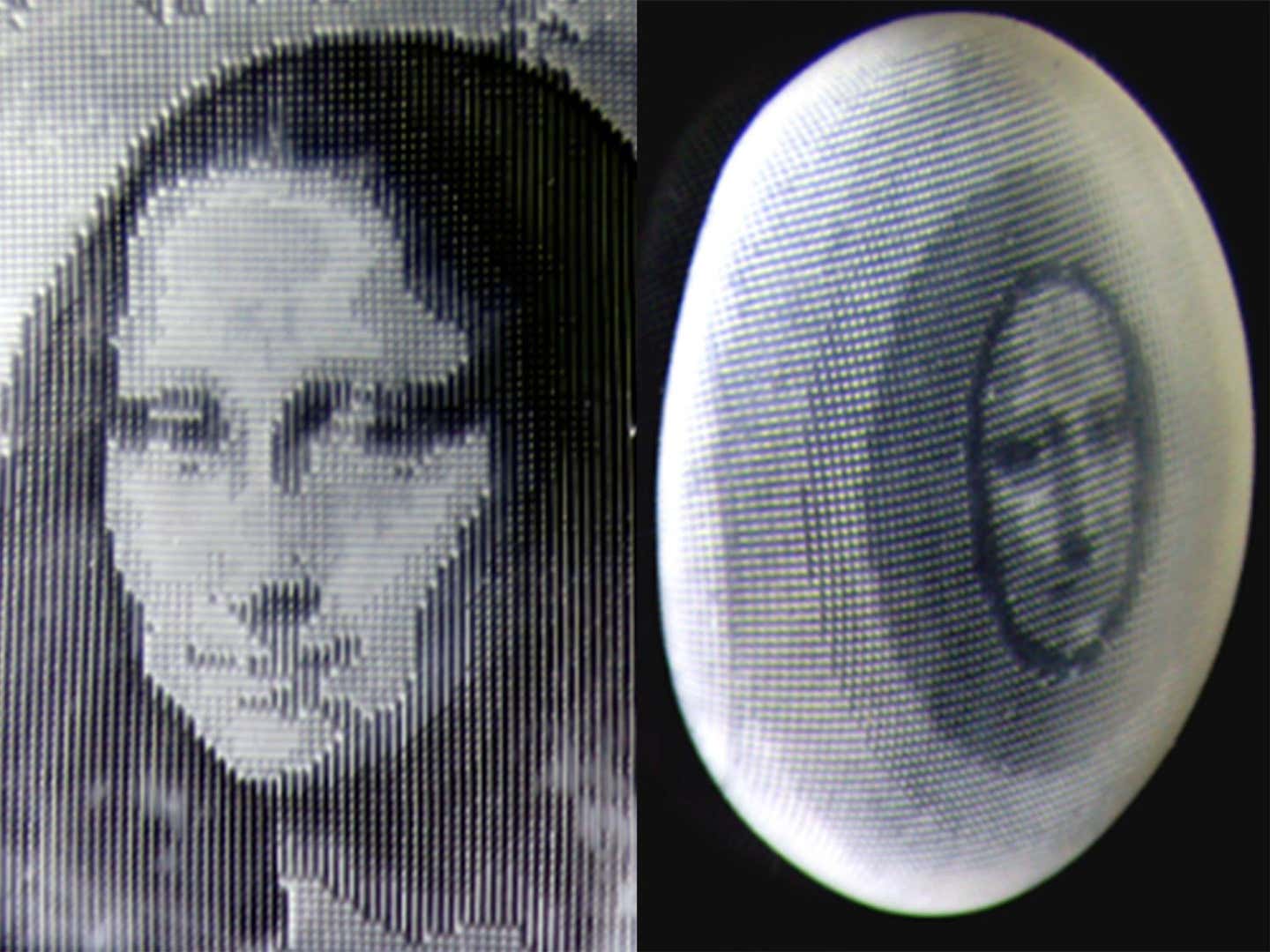

The team used their new printing method to encode a photo of the Mona Lisa onto their “smart skin” material (left). The photo, which can initially appear hidden in the material, can be revealed by stretching, exposure to heat, exposure to liquid or by adjusting the material from a 2D to a 3D shape (right). (CREDIT: Hongtao Sun)

At first glance, it looks like a plain, slightly glossy sheet. Then it goes through a quick bath, the temperature shifts, and a famous face comes back from nowhere.

In one demonstration, a film made from hydrogel, a water-rich material that feels a bit like soft contact lens plastic, suddenly brought the Mona Lisa into view. The image was not printed with ink. It was encoded into the material itself, and it stayed invisible until the right conditions flipped the switch.

That trick is part of a broader effort at Penn State to make what the researchers call a programmable “smart synthetic skin,” a thin, shape-shifting material that can be tuned to change its appearance, texture, and mechanical behavior when exposed to outside triggers like heat, solvents, or physical stress.

Hongtao Sun, an assistant professor of industrial and manufacturing engineering at Penn State and the project’s principal investigator, said the concept was inspired by cephalopods, including octopuses, which can control the look and feel of their skin to blend in or signal to each other.

“Cephalopods use a complex system of muscles and nerves to exhibit dynamic control over the appearance and texture of their skin,” Sun said. “Inspired by these soft organisms, we developed a 4D-printing system to capture that idea in a synthetic, soft material."

The team described the work in a paper published in Nature Communications, which was also featured in Editors’ Highlights.

Printing “instructions” into a soft sheet

Sun describes the method as 4D printing, meaning the researchers create a three-dimensional object whose properties can change over time in response to its environment. In this case, the object is a hydrogel film, and the “fourth dimension” is how it morphs or shifts when stimulated.

The key step is what Sun called halftone-encoded printing. In halftone printing, images are built from dot patterns, the same basic idea used in newspapers and many photographs. Here, the team used a related logic to translate image or texture data onto a surface as binary information, ones and zeros, and encode it into the material.

“In simple terms, we’re printing instructions into the material,” Sun explained. “Those instructions tell the skin how to react when something changes around it.”

Those hidden instructions shape how different regions of the hydrogel respond. When the film is exposed to changing temperature, liquids, or mechanical forces, some areas can deswell or soften more than others. When the pattern is designed carefully, the whole sheet can take on a programmed behavior, from subtle surface texture changes to dramatic shape transformations.

The Mona Lisa that disappears in ethanol

Haoqing Yang, a doctoral candidate in industrial and manufacturing engineering at Penn State and the paper’s first author, pointed to the encryption and reveal effect as one of the clearest demonstrations.

To show it, the team encoded an image of the Mona Lisa onto the smart skin. When the film was washed with ethanol, it appeared transparent, with no visible image. But after immersion in ice water, or during gradual heating, the Mona Lisa became fully visible.

Yang said the point was not the painting itself, but the flexibility. The method allows the researchers to encode any desired image into the hydrogel.

“This behavior could be used for camouflage, where a surface blends into its environment, or for information encryption, where messages are hidden and only revealed under specific conditions,” Yang said.

The group also showed that information can be uncovered through touch and deformation, not just sight. By gently stretching the film and measuring how it deforms using digital image correlation analysis, they could reveal patterns that were otherwise hidden. That opens the door to a different kind of security, where a message might require the right mechanical manipulation and the right measurement method to decode.

Texture and shape changes without layering materials

Beyond hiding and revealing images, the hydrogel proved highly malleable. Sun said the smart skin could transform from a flat sheet into bio-inspired shapes with complex textures.

Many shape-morphing materials rely on multiple layers or mixes of different materials. The Penn State approach, as described in the source material, can achieve shape and texture control through the digitally printed halftone pattern inside a single sheet.

The team pushed that idea further by showing the material can combine functions at the same time. By co-designing halftone patterns, they encoded the Mona Lisa into flat films that later transformed into 3D shapes. As the flat sheets curved into dome-like structures, the hidden image gradually became visible.

“Similar to how cephalopods coordinate body shape and skin patterning, the synthetic smart skin can simultaneously control what it looks like and how it deforms, all within a single, soft material,” Sun said.

Toughness, stretch, and engineered “subdomains”

The source material also describes a related, more technical line of work focused on how patterned hydrogel films can be engineered for stronger, tougher mechanical behavior.

In that portion, the team used spatiotemporal control over photo-polymerization, through dynamic light projection grayscale lithography in a digital light processing 3D printer, to create hydrogel films with stiff, cellular-like pattern domains embedded in softer film regions. Under stretching, these stiff patterns can create localized strain behavior in the softer regions.

The researchers report that patterned films showed more than a threefold increase in ultimate strength and an 80 to 150 percent increase in material toughness compared to a non-patterned film, based on mean values with four replicates.

They used in-situ digital image correlation strain mapping to watch how deformation localized in different subregions, and they also tracked deformation patterns using fast Fourier transform analysis of pattern domains. The source describes a “subdomain-interface mechanism,” where the interaction between more deformable and less deformable local regions helps improve global performance.

The team also reports a trade-off: increasing UV exposure time in the softer film region raised ultimate strength but reduced toughness in certain patterned films, which they link to a reduced mismatch between stiff and soft regions.

Who did the work, and what comes next

Along with Sun and Yang, the source lists other Penn State co-authors: Haotian Li and Juchen Zhang, doctoral candidates in industrial and manufacturing engineering, and Tengxiao Liu, a lecturer in biomedical engineering. The work also included H. Jerry Qi, a mechanical engineering professor at the Georgia Institute of Technology.

Sun said the group plans to develop a general and scalable platform for precise digital encoding of multiple functions into a single adaptive smart material system.

“This interdisciplinary research at the intersection of advanced manufacturing, intelligent materials and mechanics opens new opportunities with broad implications for stimulus-responsive systems, biomimetic engineering, advanced encryption technologies, biomedical devices and more,” Sun said.

Practical implications of the research

If the approach scales the way the team hopes, it points toward soft surfaces that can do more than sit there and hold shape.

A film could conceal identifying markers that only appear under a particular solvent wash or temperature shift.

A device could change surface texture or geometry without adding motors or stacking multiple materials. And because information can be revealed through deformation and measurement, not just by looking, the material could support security schemes that rely on both physical handling and sensing.

Research findings are available online in the journal Nature Communications.

The original story "Programmable hydrogel 'smart skin' can hide images, shift texture, and morph shape" is published in The Brighter Side of News.

Related Stories

- Scientists believe that insects, reptiles, amphibians, and fish could also be sentient

- Scientists engineer microbe that mass-produces camouflage pigment

- Octopus-inspired glove securely grips objects underwater

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Hannah Shavit-Weiner

Medical & Health Writer

Hannah Shavit-Weiner is a Los Angeles–based medical and health journalist for The Brighter Side of News, an online publication focused on uplifting, transformative stories from around the globe. Passionate about spotlighting groundbreaking discoveries and innovations, Hannah covers a broad spectrum of topics—from medical breakthroughs and health information to animal science. With a talent for making complex science clear and compelling, she connects readers to the advancements shaping a brighter, more hopeful future.