Researchers develop lifelike replicas of adult human ears using a 3D printer

Researchers have developed a lifelike replica of an adult human ear using cutting-edge tissue engineering methods and 3D printing technology

Researchers have developed a lifelike replica of an adult human ear using cutting-edge tissue engineering methods and 3D printing technology. (CREDIT: Shutterstock)

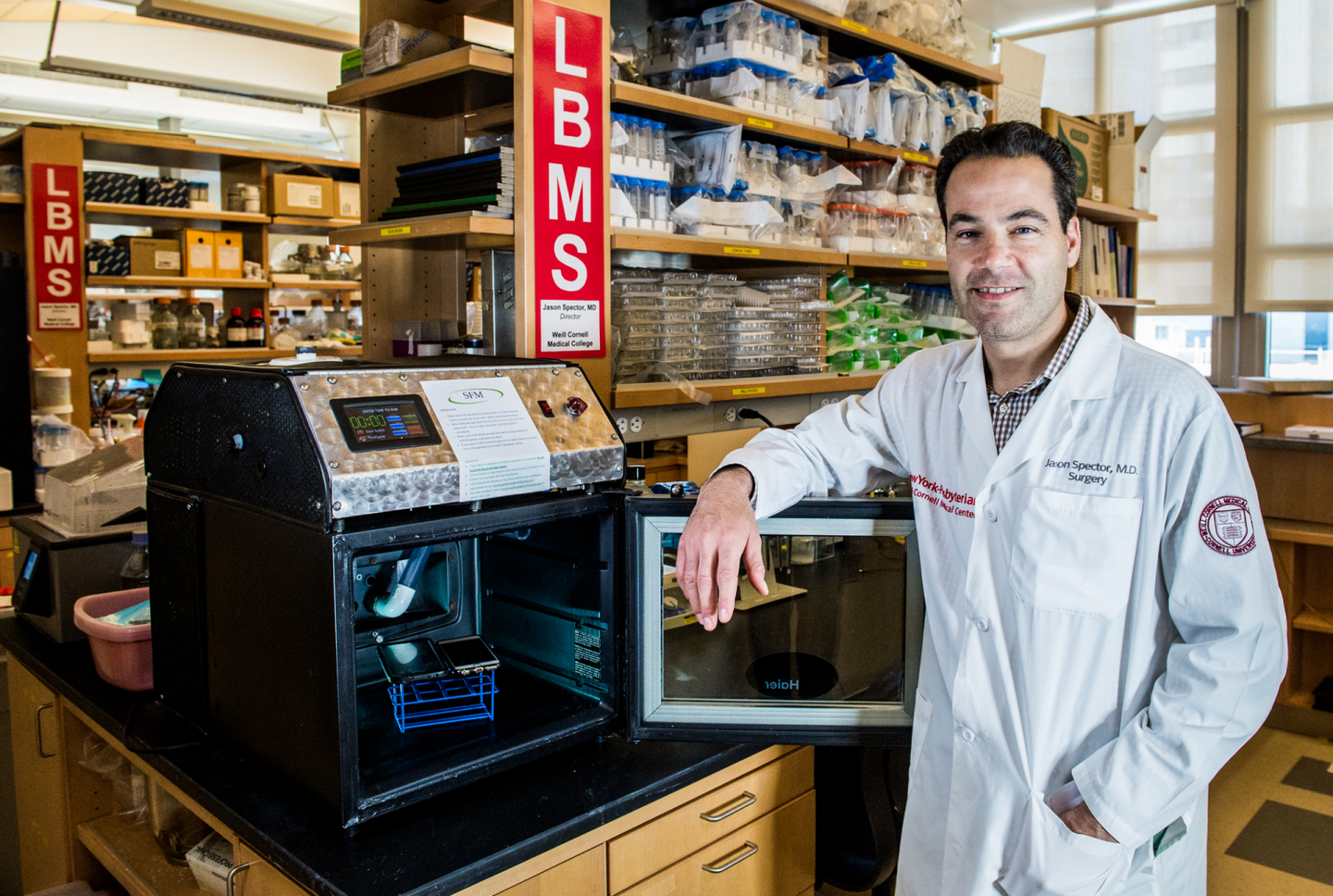

Researchers at Weill Cornell Medicine and Cornell Engineering have developed a lifelike replica of an adult human ear using cutting-edge tissue engineering methods and 3D printing technology.

The study, published in Acta Biomaterialia, holds promise for individuals born with congenital ear malformations or those who lose an ear later in life.

Dr. Jason Spector, chief of the Division of Plastic and Reconstructive Surgery at Weill Cornell Medicine, highlighted the significance of this advancement: "Ear reconstruction requires multiple surgeries and an incredible amount of artistry and finesse. This new technology may eventually provide an option that feels real for thousands needing surgery to correct outer ear deformities."

Pictured is the intricate, left-ear plastic scaffold that was created on a 3D printer based on data from a person’s ear, anterior view (left) and posterior view (right). (CREDIT: Spector Lab)

Traditionally, surgeons construct replacement ears using cartilage harvested from a child's ribs, a procedure that can be painful and leave scarring. However, the resulting graft often lacks the flexibility of a natural ear.

To address this limitation, researchers sought to enhance the natural feel of replacement ears by incorporating chondrocytes, the cells responsible for building cartilage.

Previous attempts involved using animal-derived chondrocytes to seed a collagen scaffold. While successful initially, these grafts tended to lose their distinctive ear shape over time due to contraction.

Related News

In the current study, Dr. Spector's team employed sterilized animal-derived cartilage, treated to prevent immune rejection, loaded into intricate, ear-shaped plastic scaffolds produced by a 3D printer.

These cartilage pieces acted as internal reinforcements within the scaffold, akin to rebar in construction, to stimulate the formation of new tissue and prevent contraction.

Over the course of three to six months, the structure developed into cartilage-containing tissue closely mirroring the anatomical features of a natural ear, including the helical rim, the "anti-helix" rim-inside-the-rim, and the central conchal bowl—an achievement not previously attained.

Biomechanical studies conducted in collaboration with Dr. Larry Bonassar, a professor in Biomedical Engineering at Cornell's Meinig School of Biomedical Engineering, confirmed that the replicas exhibited flexibility and elasticity similar to human ear cartilage. However, the engineered material was not as strong as natural cartilage and was prone to tearing.

To address this weakness, Dr. Spector plans to incorporate chondrocytes derived from a small piece of cartilage taken from the recipient's other ear. These cells would deposit elastic proteins characteristic of ear cartilage, resulting in a graft that closely mimics the biomechanical properties of the native ear.

Using a small animal “bioreactor”, researchers have bioengineered full-scale ears utilizing decellularized cartilage xenograft placed within a 3D-printed external auricular scaffold that mimics the size. (CREDIT: Acta Biomaterialia)

This groundbreaking research offers hope for individuals in need of ear reconstruction by providing a viable alternative to traditional methods. With further refinement, this technology has the potential to revolutionize the field of reconstructive surgery, offering patients a natural-looking and feeling solution to outer ear deformities.

This work was supported in part by the National Center for Advancing Translational Sciences of the National Institutes of Health, grant TL1- TR-002386.

For more science and technology stories check out our New Innovations section at The Brighter Side of News.

Note: Materials provided above by the The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.