Scientists create 4D bioprinted tissue that changes shape just like real tissues do

A new 4D bioprinting method mimics how organs form in embryos, allowing lab-grown heart tissues to develop strength and structure.

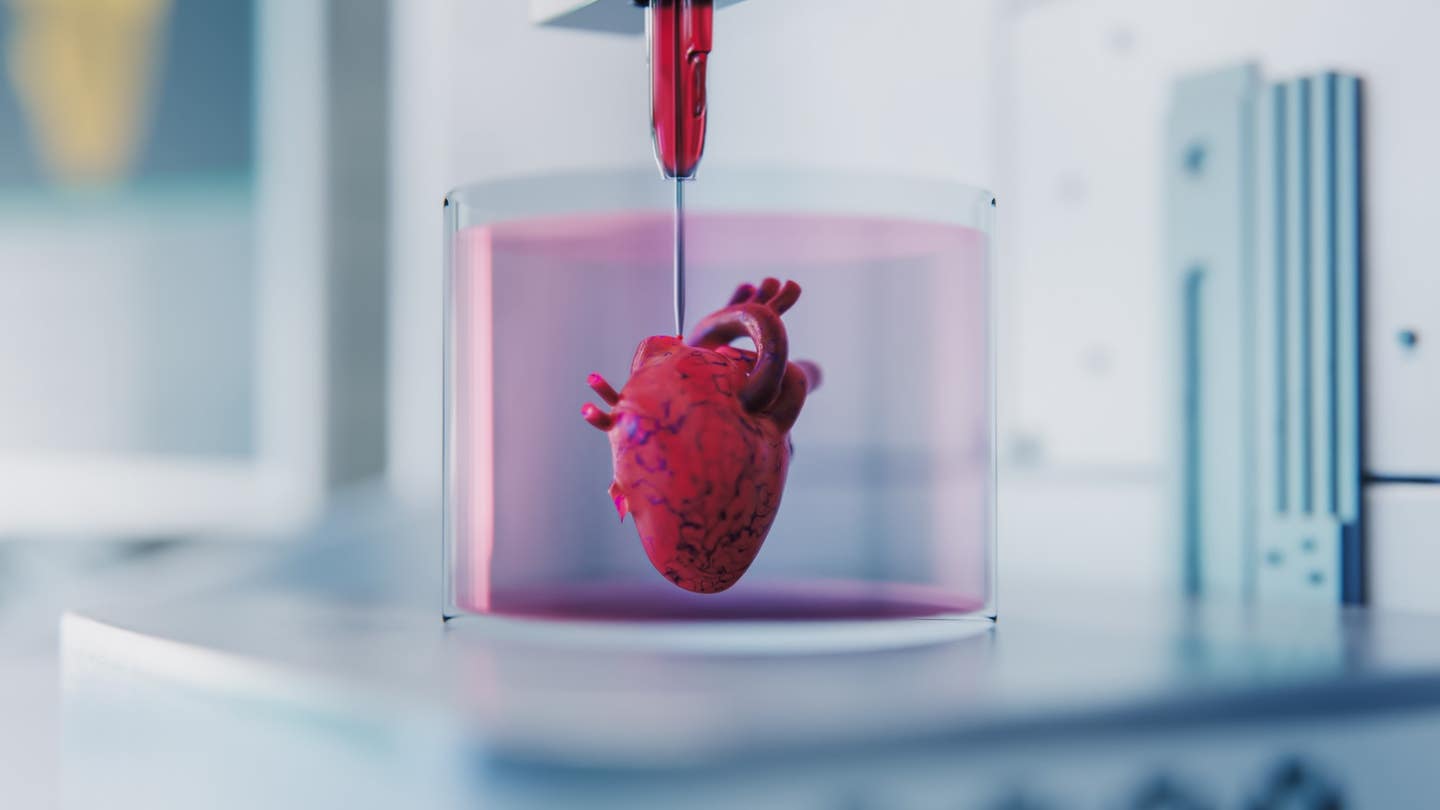

New 4D bioprinting lets tissues change shape and grow stronger, bringing science closer to real, working lab-grown organs. (CREDIT: Adobe Stock)

During the early stages of life, organs do not just appear in their final form. They take shape through a process of controlled bending, twisting, and folding. These changes help cells organize into functional structures.

Until now, most attempts to bioprint organs skipped this important step. Scientists printed tissues in their final shape, hoping they would work like natural organs. But this approach failed to copy the active shaping that happens during early development.

That’s what makes a recent breakthrough so important. A research team at the University of Galway has created a new way to 4D bioprint tissues that can change shape in a controlled way—just like real tissues do as they form. This discovery brings science closer to building working organs in the lab.

A New Way to Shape Life

The team, led by professor Andrew Daly, has developed a method that lets bioprinted tissues bend and twist on their own after printing. This process mimics the way tissues change shape naturally during embryonic development.

The project was led by researchers from the School of Engineering and the CÚRAM Research Centre for Medical Devices. Their work, published in Advanced Functional Materials, focused mainly on heart tissue.

The researchers used something called “embedded bioprinting.” This means they printed the tissue into a soft, jelly-like material that supports it while it forms. The bioink they used was made from collagen and hyaluronic acid, both of which help cells grow and stick together. The supporting gel allowed the tissue to move and change shape without collapsing.

Related Stories

But what really sets this process apart is how the tissues move. The changes are not random. The printed tissues morph into specific shapes, driven by the forces generated by the cells themselves. Scientists programmed these changes by adjusting the original print design, the types of cells used, the stiffness of the materials, and even the softness of the support gel.

Why Shape-Morphing Matters

The human heart doesn’t start out as a four-chambered pump. In the womb, it begins as a simple tube. Over time, it twists and folds into its final form. This shaping process is crucial. It not only gives the heart its structure but also tells the cells how to align and function.

The Galway team knew that trying to skip this step in bioprinting might explain why printed heart tissues don’t work as well as they should. Although they can beat, the strength of the contractions is much weaker than that of a healthy adult heart.

“We found that shape-morphing improved the structural and functional maturity of bioprinted heart tissues,” said Ankita Pramanick, a PhD student at the university and lead author of the study. “Our tissues started to act more like real heart tissue.”

The shape changes did more than just make the tissues look like real hearts. They also helped the cells line up properly, which is vital for muscle contraction. The movement directed how both the cells and the surrounding support material arranged themselves. This allowed the tissue to beat more strongly and more regularly.

Designing Movement With Precision

To better understand and control how these tissues change shape, the researchers built a computer model. This tool can predict how a printed tissue will evolve over time, based on the starting conditions. The model includes both the cells and the full tissue structure, helping scientists design prints that morph into the desired shapes.

One of the most powerful parts of the study was the ability to program movement. By tweaking the original print layout, bioink mixture, and gel properties, the team could decide exactly how the tissue would fold or bend. This makes the method both repeatable and customizable, a major step forward in tissue engineering.

Daly explained the project's potential, saying, “Our research shows that by allowing bioprinted heart tissues to undergo shape-morphing, they start to beat stronger and faster. The limited maturity of bioprinted tissues has been a major challenge in the field, so this was an exciting result for us.”

What This Could Mean for the Future

This new process opens many doors. It brings researchers closer to building lab-grown organs that work more like real ones. This could change how we model diseases, test new drugs, or even replace damaged organs.

But there’s still a long road ahead. “We are still a long way away from bioprinting functional tissue that could be implanted in humans,” Professor Daly said. One major challenge will be scaling up the tissues to the size of human organs. Large tissues need blood vessels to survive, and those are difficult to print.

Still, the future looks hopeful. “This allows us to create more advanced bioprinted heart tissue, with the ability to mature in a laboratory setting, better replicating adult human heart structure,” Daly added.

His team plans to expand this work as part of a European Research Council project. They aim to apply these shape-changing methods to other organs and continue learning how to guide tissues to form naturally.

This discovery shifts how scientists think about tissue engineering. Instead of printing organs as finished products, the focus is now on printing a starting point—and then letting the tissues grow, change, and mature just like they do in the womb.

The ability to program and predict these shape changes brings us one step closer to printing organs that not only look real but also work like the real thing.

Note: The article above provided above by The Brighter Side of News.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.