Scientists create microscopic machines powered by light

Researchers have built light-driven microscopic machines the size of cells, opening new paths for medicine, robotics, and microchips.

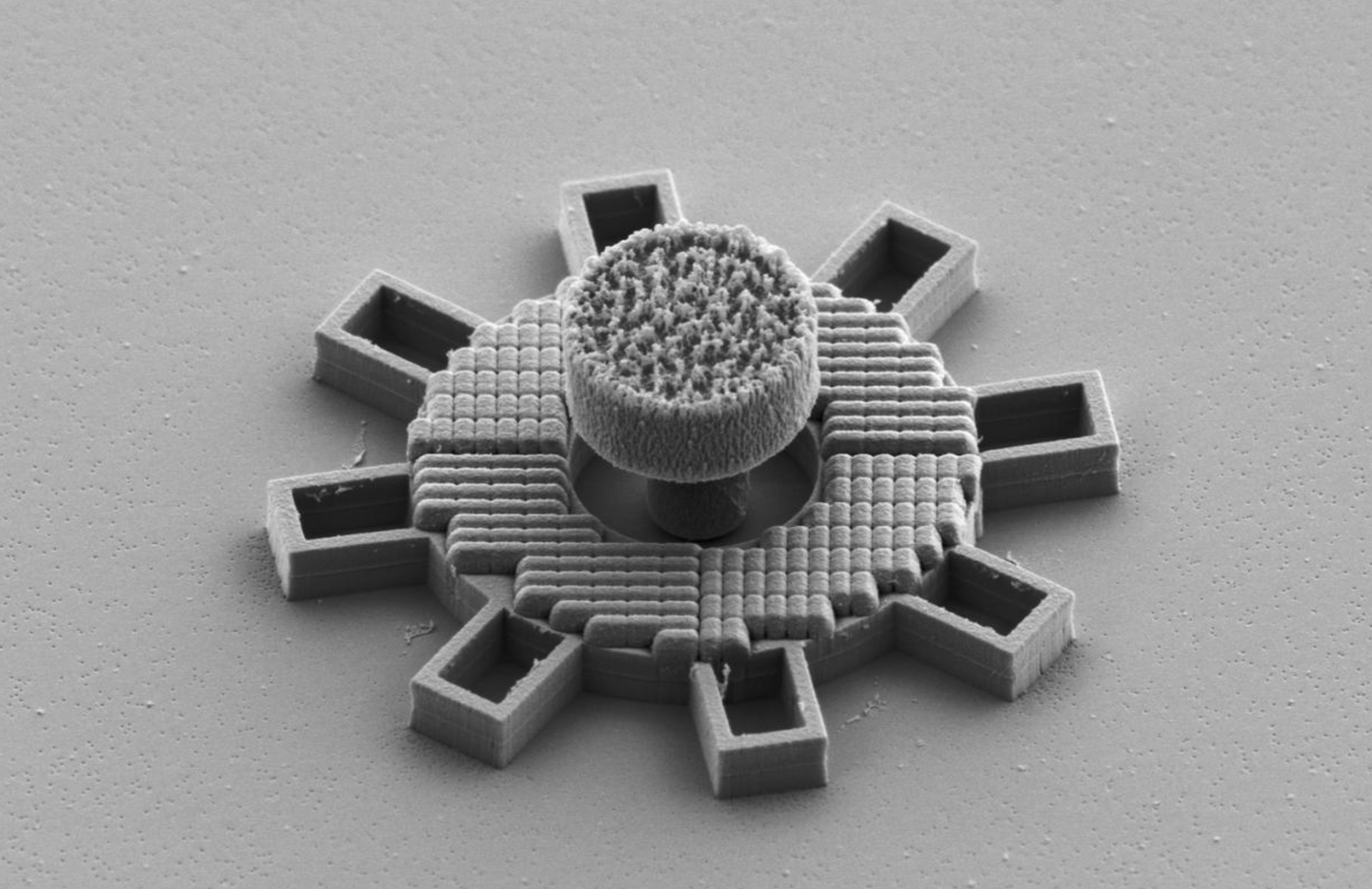

The gear moves when its light-responsive structure is activated. (CREDIT: Gan Wang)

Gears have powered the world for millennia, from clock machines to car engines. But miniaturizing them to microscopic dimensions has stumped engineers for decades. Anything under one-tenth of a millimeter faced the same barriers: too much bulk from wire, magnets, and couplings, and no decent method for propelling them.

And now, one group has found a means to break through that limit. Instead of relying on traditional drive trains, they've turned to light itself. By using cleverly designed surfaces that bend and steer photons, researchers have built "metamachines" — microscopic mechanical devices that can rotate, join themselves, and even translate rotational motion into linear motion.

Gan Wang, a physicist at the University of Gothenburg and the lead author on the paper, calls it "a fundamentally new way of thinking about mechanics on a microscale."

How Light Powers a Machine

The technology relies on metasurfaces, thin sheets of material with patterns inscribed on them that manipulate light. The silicon-based surfaces are fabricated directly onto microchips using the same technologies to manufacture computer processors.

Researchers made ring-shaped rotors called "metarotors" to support the optical metasurfaces. When a ring is illuminated with a laser beam, the surface structure diffuses the light. Because momentum cannot be lost, the pressure of the light creates an infinitesimal torque that rotates the ring.

The result is a working gear just a few micrometers across—about the size of a human cell. Changing the power of the laser causes the gear to spin more or less rapidly. Altering the polarization of the light even makes its direction reverse.

Building Tiny Gear Trains

The success did not stop at standalone gears. The researchers coupled numerous gears together in trains, with the rotation of one energizing the other. Depending on the relative diameter of each gear, torque could be multiplied or speed multiplied, such as in full-scale machinery.

In a test, the scientists built gear trains of three, four, and five wheels. With more gears, the speed of the system fell more quickly than the mathematics had anticipated, primarily because of higher friction at each contact point. Regardless of this, the trains worked as predicted by mathematics.

The team also demonstrated a rack-and-pinion setup, where the rotation of a gear was converted into a back-and-forth sliding motion. With one setup, altering the polarization of the light made the rack move in reverse directions. With the other, the rack itself was patterned with metasurfaces so that it oscillated when exposed to continuous light.

This range of motion shows that the machines aren't just turning wheels. They're doing work that, until now, was only possible in big-scale mechanics.

Permanent, Yet Small

The smallest gears made to date are only eight micrometers wide. For perspective, a red blood cell is approximately the same width. Though they appear delicate, the machines proved remarkably resilient. They operated for 11 hours in light continuously without breaking and could be kept in storage for six months without compromising functionality.

Their performance actually decreased with age, usually from fluid environment changes in the surrounding fluid, e.g., contamination or surface coating variations. But rejuvenating the fluid returned to full speed, which shows the gears themselves worked incredibly well.

A New Kind of Microengineering

What is so exciting about this approach is that it can exist alongside existing chip-making methods. As the devices are etched and constructed with the same technology as those in semiconductor plants, producing large numbers at once is possible.

Light as an energy source has one more great advantage. It has no wires, no large magnets, and no physical contacts. It can be directed, focused, and tuned with high selectivity. At the near-infrared wavelength employed by the researchers—1,064 nanometers—the light is harmless to many biological tissues since it will not easily cause tissue or water damage.

This is an entirely new way of thinking about the mechanics," Wang said. "By replacing heavy couplings with light ones, we can finally overcome the size limitation."

Medical and Technological Potential

Because the machines are on the order of cell size, there is fascinating medical potential. Wang believes micromotors could one day be used as body pumps or valves to regulate flows or close and open channels. The fact that they are compatible with optical systems also makes them good bets for tiny sensors, micromirrors, or switches in lab-on-a-chip chips.

The effectiveness of the current designs remains low, and heating effects due to high light intensity can become an issue. But the concept has already opened the door to using collective arrays of such machines to drive particles, move fluids, or manipulate light in ways that were impossible on this scale.

The research forecasts that in the future, machines of the order of living cells can be as pervasive in medical devices and optical systems as gears are now in watches and cars.

Practical Implications of the Research

This technology can potentially transform the powering and construction of microscopic systems. By avoiding wiring or magnets, engineers can design micro- and nanomachines that are easily embedded in chips or even biological systems.

The technology could ultimately power medical implant pumps, turn on new lab-on-a-chip diagnostic devices, and provide optical switches for communications systems. This means for humans faster, safer, and more compact technologies in medicine, computing, and research.

Research findings are available online in the journal Nature Communications.

Related Stories

- Autonomous microrobot sets new standard for precision surgery deep inside the body

- Tiny laser revolutionizes precision measurement and self-driving technology

- Tiny Particle Accelerator Is Millions of Times Smaller Than CERN's Large Hadron Collider

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Writer and Editor

Joshua Shavit is a Nor Cal-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a co-founder of The Brighter Side of News, he focuses on positive and transformative advancements in technology, physics, engineering, robotics and astronomy. Joshua's work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.