Scientists develop clean and efficient new method for iron and steel production

Scientists use hydrogen plasma to cut steel’s carbon emissions, reducing iron ore at room temperature and producing only water.

Researchers have shown how hydrogen plasma can reduce iron ore at room temperature, offering a path to cleaner and cheaper steel production. (CREDIT: Shutterstock)

Steel has underpinned modern life for centuries, but it comes at an expensive cost. The industry is responsible for nearly 7 percent of the world's total carbon dioxide emissions, driven by blast furnaces fueled by coke, a form of coal, to extract oxygen from iron ore. For decades, most attempts at cleaner steel-making, though, have been dashed on the problem of doing it large-scale. Scientists may now have an answer.

Transitioning to Hydrogen Plasmas

Scientists have long dreamed of using hydrogen as a cleaner alternative to coke. Theoretically, if hydrogen gas is used to smelt iron ore, the waste product would be nothing but water. But the method has languished behind thermodynamic hurdles. Smelting magnetite, the most common iron ore, with hydrogen alone demands extremely high temperatures above 900 Kelvin and then even hotter stages to complete the reaction. The result is substantial cost and substantial energy usage.

Researchers at the University of Minnesota Twin Cities, working in partnership with Hummingbird Scientific, have now shown how hydrogen plasmas that are not thermal can change the paradigm. As opposed to reactions from heat, these plasmas form fleeting but highly energetic hydrogen radicals—atoms so reactive that they can smelt iron ore at room temperature.

Watching the Reaction in Real Time

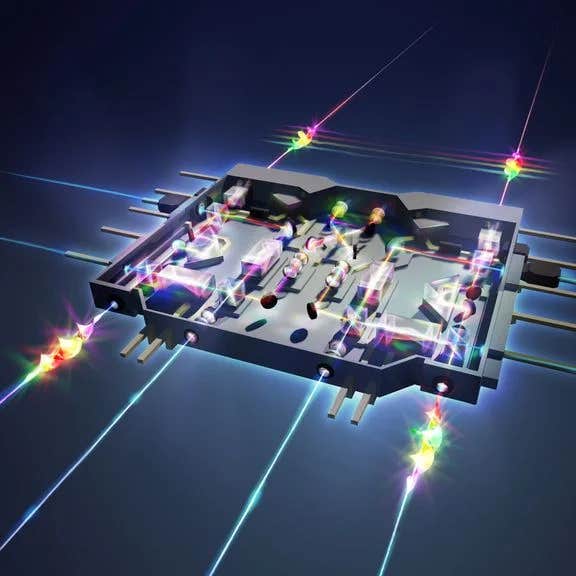

Until recently, no one had seen what these reactions looked like on the tiniest scales. Other experiments employed bulk samples that masked the fine details within disordered structures. To get around this problem, researchers developed a new device called operando plasma transmission electron microscopy, or TEM.

This instrument can image magnetite nanoparticles directly upon exposure to hydrogen plasma at a resolution of around one nanometer. That's ten times better than earlier optical methods and allows researchers to watch the process in real-time.

"We developed a new technique that allows us to probe plasma-material interactions at the nanometer scale, which has not been achievable so far," said Jae Hyun Nam, lead author of the paper and graduate student in the mechanical engineering department at the University of Minnesota.

Cracks, Shrinkage, and Iron Formation

What the researchers saw was a drama. In ten seconds of exposure, magnetite particles began shrinking and developing cracks. At an atomic level, hydrogen radicals were stripping oxygen from the crystal structure, leaving metallic iron behind.

The particles followed a shrinking-core model, where the reaction initiated on the surface and propagated inward, relentlessly dissolving away the oxide. That meant that the reaction rate was governed by surface chemical steps rather than by transport across the particle. Scaling up is good news, as it suggests the focus should be put on controlling plasma radical density rather than worrying about diffusion through large chunks of ore.

"Plasma formation can be energetically much more efficient than heating the material," said Andre Mkhoyan, lead author on the paper and professor in chemical engineering and materials science at the University of Minnesota. "This technology has the potential to enable materials to be altered with lower energy consumption, ultimately making processes economically more efficient."

Engineering the Microscope

Building the operando TEM setup was not a job for the faint of heart. To work plasma inside a microscope, the scientists developed a bespoke cell out of two silicon chips with extremely thin membranes. Electrodes only 60 micrometers apart, about the thickness of a human hair, generated the discharge, and shielding coatings shielded the system from being destroyed.

"Getting around the technical challenges of this work was one of the hardest experiments we've ever conducted," said Peter Bruggeman, senior author of the study and Distinguished McKnight University Professor in the University of Minnesota. "Producing plasmas of a scale on the order of the size of a human hair is quite challenging engineering-wise which we collaborated to get around with Hummingbird Scientific."

The payoff was full-color pictures of particles shrinking and fragmenting in real time. For the first time ever, scientists could confirm decades of supposition that plasma species lower the activation barrier for iron oxide reduction.

Beyond the Lab

The findings, published in Nature Communications, are not just specific to steel. The ability to image plasma-material interfaces at the nanoscale could open up new possibilities for catalysis, fabrication of nanomaterials, and energy storage. By trapping transient chemical states that disappeared too quickly to be observed before, the operando TEM method provides scientists with a potent new lens.

Nevertheless, the greatest potential comes in ironmaking itself. If hydrogen plasmas can be used to substitute for coke in furnaces, the steel industry would reduce its emissions significantly. With water as the sole byproduct, the process would be one of the cleanest ever created for one of the world's most crucial materials.

Practical Implications of the Research

The new plasma-based method could slash the carbon footprint of steelmaking, perhaps the most carbon-intensive industry to decarbonize. The process saves energy, lowers costs, and produces only water as a byproduct with the success of hydrogen-based iron reduction at room temperature.

Besides steel, the operando plasma TEM platform offers a means to improve catalysts, create superior materials, and optimize energy technologies.

These innovations can stimulate the shift to cleaner production and provide industries with alternatives to existing carbon-based practices that are scalable and efficient.

Related Stories

- 3000-year-old copper smelting site reveals the dawn of iron age technology

- New 'Super Steel' pulls green hydrogen directly out of seawater

- Scientists develop an environmentally-friendly method for making steel using electricity

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Shy Cohen

Writer