Scientists just built a laser entirely out of peanuts and birch leaves

Scientists built a laser from birch leaves and a peanut, offering a safe and low-cost path for future medical imaging tools.

Edited By: Joseph Shavit

Edited By: Joseph Shavit

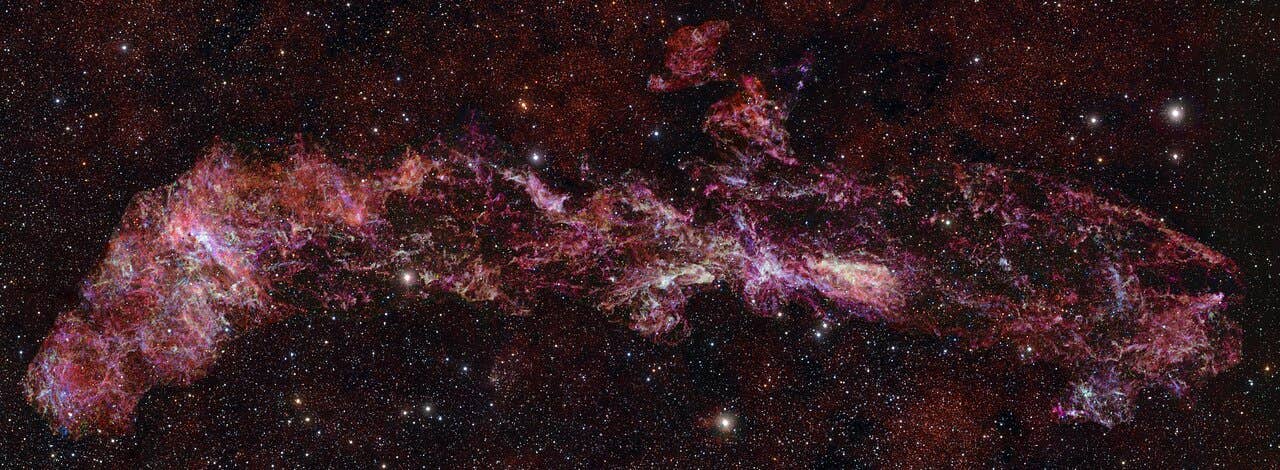

The biomaterial-based random laser when activated. (CREDIT: Zhihao Huang)

A regular medical examination can already feel daunting amid the uncertainty of what doctors will discover. Behind every scan is a hesitant hope that the technology works well, feels safe, and does not break the bank.

That hope is not lost on the physicists dedicated to studying how light propagates through the body. Many hope to engineer imaging devices that will facilitate our feeling seen and not exposed. A team working collaboratively across Sweden and China is now a little closer to that dream by starting with something as commonplace as a peanut.

How a Peanut Became a Light Source

Researchers at Umeå University and partner labs in China were on a quest to make a laser made entirely from naturally occurring materials. They wanted an apparatus that was powerful enough for medical sensing and mild enough to ambulate in soft tissues without toxic additives.

Most lasers in labs and clinics are based on synthetic dyes or engineered crystals that can break down, harm cells, or be too expensive to use. In contrast, the goal was to find something that was clean, stable, and relatively cheap.

They found their answer in birch leaves and the kernel of a peanut. The birch leaves were processed into glowing carbon dots. These smaller particles have been reported in the scientific literature since 2004, but they can shine brightly, resist fading, and they can't poison cells.

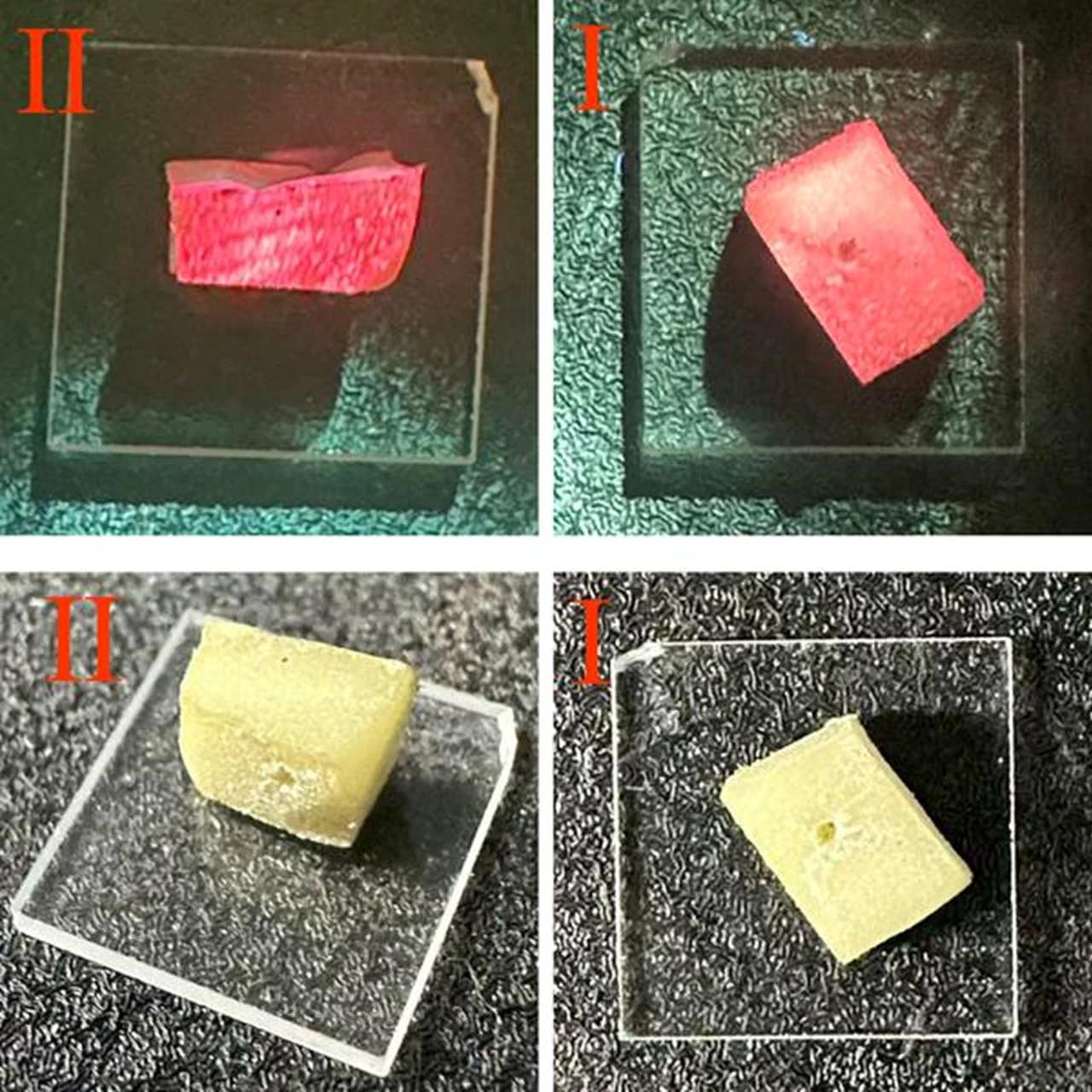

The red light they emit can travel deeper into tissues than many of the common imaging dyes. The peanut is responsible for the remainder of the structure. When a slice was processed into a small block, it gave a surface that was both naturally coarse and porous, allowing light to be captured and scattered in all directions.

You might consider a laser as a couple of mirrors reflecting light back and forth until it shines as a narrow beam. A random laser operates differently. Rather than mirrors, a random laser employs a chaotic landscape to focus light. In this device, the peanut’s folds and cavities formed a playful maze that required the photons to ricochet around until they had amassed enough gain.

Simple Steps Behind a Complicated Task

The researchers constructed the device by injecting the leaf-derived carbon dots into several areas inside the peanut block. The solution pooled in between the cells of the peanut, and then drying the peanut at a very gentle heat removed the excess liquid. When the peanut cooled down, many millions of glowing tiny particles were suspended inside the peanut.

The researchers did not need to worry about whether or not the carbon dots would stay bright, as they demonstrated in the preliminary tests. The peanut had a faint blue glow, but based on the faint output from the host material, the extremely strong red glow measured at 686 nanometers. The surface under a microscope was like a topographical map formed by the passage of time.

Deep folds, tiny wrinkles; unfussy pores about 50 micrometers across; all creating the disorder that is necessary for random lasing to occur. All of this complexity was not intentional; it was just the outcome of the way the peanut grew. Utilizing pulsed light sources aimed at the peanut that was treated, the group observed the sample shift from a soft red glow to sharp peaks of emission from the laser.

Each of the five surfaces tested lased at a different power threshold. The nearest surface to the initial site of injection required less power than surfaces away from the injection site. The power thresholds ranged from 96.4 kilowatts per square centimeter to 150.3 kilowatts per square centimeter, values comparable to many engineered laser systems.

The laser images collected during analysis indicated bright points appeared across the surface of the laser after the threshold had been reached. These luminescent points indicated locations where photons had collided and contributed to amplification within the laser. The bright points multiplied with increasing power input. They manifested in a pattern that appeared random; however, collectively, the bright points created stable and useful output.

Why This Is Important for Patients and Researchers

For any of you that has waited for medical results often, the type of laser in the scan is about as far away from daily life as you can get, until you see your images in a doctor's office. But the image quality from the scan, the safety of the dyes used, and the costs of the equipment and procedure can influence outcomes and diagnostics.

A random laser produced from a natural material avoids any speckle noise often associated with images obtained from the traditional laser. The random lasers produce generically smoother images of tissues and cells, which can contribute to the palette of health variations that can lead to earlier detection of disease.

Given that each peanut laser can have a highly unique internal structure, each optical laser pattern can be used like a fingerprint. This could help with identifying levels of a product or a document, essentially acting as a natural security tag or marker that is difficult to generate or fabricate. The materials being bio-compatible present a future use in wearable sensors, non-invasive diagnostics, or real-world imaging.

Jia Wang, an associate professor involved in the study, indicated that the work intended to demonstrate that there is a method of creating advanced optical devices more simply. "The synthesis of the carbon dots is relatively easy and well accepted," she stated. "This is just another example of how other, second-class technology can be developed without the use of complex technology," she added. "This easily accomplishes the task, using the natural microstructure of the peanut kernel."

Research findings are available online in the journal Nanophotonics.

Related Stories

- New laser technique reveals nearly 20 previously hidden states of matter

- Cheaper, faster, stronger: Scientists develop the next generation of smart lasers

- Scientists fire most powerful US laser ever—100 times Earth's total energy usage

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Rebecca Shavit

Writer

Based in Los Angeles, Rebecca Shavit is a dedicated science and technology journalist who writes for The Brighter Side of News, an online publication committed to highlighting positive and transformative stories from around the world. Her reporting spans a wide range of topics, from cutting-edge medical breakthroughs to historical discoveries and innovations. With a keen ability to translate complex concepts into engaging and accessible stories, she makes science and innovation relatable to a broad audience.