‘Chinese lantern’ material snaps into 13 shapes using stored elastic energy

A team at NC State has created a “snapping” material that shifts into 13 shapes using elastic energy and magnetism.

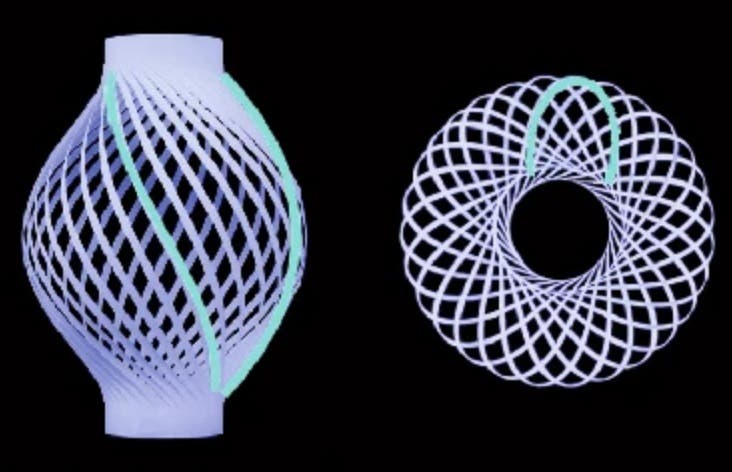

Scientists create a shape-shifting material that snaps into 13 forms using stored energy and magnetic fields. (CREDIT: Nature Materials)

A new kind of shape-shifting material can twist, bend, and snap into more than a dozen three-dimensional forms—no motors or wires required. Using stored elastic energy, it transforms itself much like a Venus flytrap snapping shut or a flower blooming.

Researchers at North Carolina State University, led by mechanical and aerospace engineering professor Jie Yin, call it a breakthrough in “snapping morphogenesis.” Their work shows how a cluster of curved ribbons can be reprogrammed to switch between multiple stable shapes on demand.

Inspired by Nature’s Snap

In the natural world, snapping movements happen when stored energy suddenly releases—think of a Venus flytrap’s quick bite or seed pods that burst open. The NC State team mimicked this concept using flexible polymer ribbons arranged around a central axis to form a lantern-like structure.

“The basic shape is, by itself, bistable,” Yin explained. “It’s stable in its lantern form, but if you push down from the top, it deforms until it suddenly snaps into a second shape resembling a spinning top. When you release it, the energy stored during compression causes it to snap back instantly.”

By tweaking angles and folds, the team found that the same structure could hold many more stable forms. Some designs could flip between two shapes, while others offered as many as four distinct configurations, depending on whether the structure was compressed, twisted, or both.

Reprogramming Shape Through Geometry

The system’s versatility comes from three key design angles: beta, gamma, and alpha. These determine how the ribbons curve, twist, and flip. Changing these angles lets the researchers control the number and nature of stable shapes.

Beta controls how each ribbon bends when assembled. Gamma determines the twist between ribbons. Alpha acts like a switch—flipping parts of the structure inward or outward to change how the elastic energy is stored. By adjusting these parameters, the researchers could “reprogram” the structure even after fabrication.

“This model allows us to program the shape we want to create, how stable it is, and how powerful it can be when stored potential energy is released,” said Yaoye Hong, the study’s first author and now a postdoctoral researcher at the University of Pennsylvania. “That’s critical for creating shapes that can perform real applications.”

Snapping With Magnetic Precision

To move from theory to demonstration, the team attached thin magnetic films to parts of the polymer ribbons. When a magnetic field was applied, it triggered the unit to compress or twist—causing it to snap from one shape to another without any physical contact.

In one test, the researchers showed how the material could act like a flower blooming under a rotating magnetic field. In another, they built a small valve that snapped open and closed to regulate water flow. They also created a soft robotic gripper that closed rapidly around delicate objects like fish—demonstrating the material’s potential for underwater robotics.

Each transformation was fast, reversible, and repeatable, controlled entirely through magnetic signals. The team even captured video of the system in action, showing a “bud-to-bloom” transition similar to a plant opening in time-lapse.

Many Shapes, One Design

What makes this system remarkable is its ability to produce multiple distinct 3D shapes from a single design. Earlier materials could typically switch between only one or two stable states. This new approach produced at least 13 different configurations using one set of ribbons.

That range is made possible by what the researchers call “nastic coupling”—a coordinated interaction between ribbons that helps the unit pick the correct snapping path when triggered. The structure doesn’t need external programming to decide which shape to take; it makes that choice naturally based on internal stresses.

In other words, the system behaves like a mechanical brain, choosing its next form based on how energy moves through it. That capability hints at the potential for future devices that perform logic operations mechanically instead of electronically.

A Framework for Future Devices

Mechanical metamaterials—engineered materials whose properties depend more on structure than substance—are already reshaping engineering and robotics. This new snapping framework adds reprogrammability and autonomy to the mix.

“Moving forward, these lantern units can be assembled into 2D and 3D architectures for broad applications in shape-morphing materials and robotics,” Yin said.

Because each unit can be controlled remotely and switched among multiple shapes, large arrays could one day work together as flexible skins, deployable systems, or even components of mechanical computers. The system’s scalability means it could work at both micro and macro levels—from tiny biomedical devices to foldable robots.

The researchers also developed detailed mathematical models predicting how each geometric configuration would behave. These “phase diagrams” help identify safe operating zones and prevent the structure from collapsing under excess strain. While 13 shapes were demonstrated, the actual limit may be even higher.

Overcoming Challenges

Scaling the design presents both opportunities and hurdles. Smaller versions may face new material constraints, while larger ones could struggle with precision and stability. Reliable control of post-fabrication flipping also remains a challenge, as do manufacturing tolerances for intricate ribbon designs.

Still, the underlying idea is robust: storing elastic energy and releasing it through carefully designed coupling. That principle can be adapted to many materials and sizes, giving engineers a flexible foundation to build on.

The possibilities are vast. Imagine surgical tools that change shape inside the human body, soft robots that slip through tight spaces before expanding, or energy-efficient mechanical systems that compute using movement instead of electricity. The NC State study provides a fundamental blueprint for all of these.

By combining geometry, elasticity, and magnetism, the researchers have shown that complex motion doesn’t require complex machinery. Sometimes, it just takes a clever design—and a little stored energy.

Practical Implications of the Research

This discovery could reshape the future of robotics, materials science, and even medicine. In soft robotics, it offers a way to build lightweight machines that can grip, crawl, or swim without motors or cables. For medical applications, remotely controlled, shape-morphing tools could allow minimally invasive procedures or targeted delivery of treatments.

The same principles could apply to deployable structures, such as antennas, stents, or even space habitats that unfold autonomously.

On a broader level, mechanical logic systems made from these reprogrammable units could reduce dependence on electronics, paving the way for durable, energy-efficient computing in extreme environments.

Research findings are available online in the journal Nature Materials.

Related Stories

- Engineers reinvent the parachute using Japanese paper-cutting art Kirigami

- Soft magnetic metamaterial revolutionizes implantable, ingestible devices

- New squishy material could make future devices faster and more energy efficient

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Science & Technology Writer and Editor

Joshua Shavit is a Los Angeles-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a co-founder of The Brighter Side of News, he focuses on positive and transformative advancements in AI, technology, physics, engineering, robotics and space science. Joshua is currently working towards a Bachelor of Science in Business and Industrial Engineering at the University of California, Berkeley. He combines his academic background with a talent for storytelling, making complex scientific discoveries engaging and accessible. His work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.