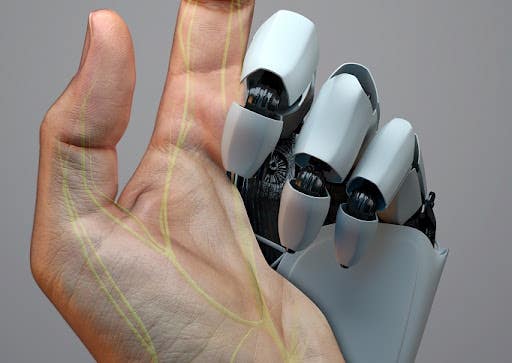

Intelligent electronics enable human-like touch and feel in extended reality

Laser ablation in liquids creates ultra-clean nanoparticles, enhancing artificial sensory systems for immersive virtual reality.

Innovative laser techniques are producing ultra-clean nanoparticles, promising major advancements in artificial sensory systems. (CREDIT: KAIST)

Advanced virtual reality (VR) and augmented reality (AR) technologies, collectively known as extended reality (XR), are becoming more integrated into everyday life. To achieve realistic experiences, devices must precisely mimic human senses. Scientists now highlight an innovative method for producing nanoparticles (NPs)—tiny particles that could dramatically enhance artificial sensory systems (ASS).

Nanoparticles offer unique benefits for ASS, like increased sensitivity, rapid response, and adaptability. However, traditional methods of producing these nanoparticles involve complex chemical processes or energy-intensive vacuum techniques. These methods often leave behind unwanted residues or contaminants, reducing device performance.

Cleaner, Customizable Nanoparticles

A recent review introduces a powerful alternative: laser ablation in liquids (LAL). Using extremely short pulses of laser light directed at solid metals submerged in liquid, LAL produces ultra-clean, customizable nanoparticles. Unlike traditional techniques, it doesn't require harsh chemicals, surfactants, or complicated post-processing.

“Laser ablation in liquids offers a clean and scalable way to produce high-performance nanomaterials,” explains Prof. Sungjun Park from Ajou University, the lead researcher. "This could fundamentally change how we design and integrate materials for flexible electronics and smart sensory systems."

Understanding Laser Ablation in Liquids

When a laser strikes a metal target in liquid, it creates a high-energy plasma. This plasma quickly cools down, forming nanoparticles whose properties—like size, shape, and chemical makeup—can be precisely controlled. Factors such as laser intensity, pulse length, wavelength, and the type of liquid used influence the resulting nanoparticles. By fine-tuning these parameters, scientists achieve nanoparticles tailored specifically for electronic sensory applications.

Recent engineering advancements have further improved LAL's efficiency and scalability. Techniques such as continuous flow systems, precise laser steering, and laser fragmentation or melting help control particle formation better and increase production rates. Current systems now produce nanoparticles efficiently enough for large-scale manufacturing.

Related Stories

- Scientists make plant-based foods more appealing using extended reality

- Groundbreaking new device could let you taste food in virtual reality

- New VR music platform enables real-time virtual performances

Nanoparticles Boost Sensory Precision

ASS mimic human senses—vision, hearing, taste, smell, and touch—enabling realistic interactions in virtual worlds or enhancing prosthetic devices. Incorporating nanoparticles dramatically improves their performance. Because LAL-produced nanoparticles are contaminant-free, they interact more effectively with their environments, offering faster, more sensitive sensory responses.

For instance, noble metal nanoparticles made through LAL significantly enhance visual or gas sensors due to their unique optical properties. Alloy nanoparticles or core-shell structures—nanoparticles with distinct inner and outer layers—show potential in sophisticated devices like hydrogen sensors and artificial synapses.

High-entropy alloys, which blend multiple metals, are particularly promising for applications that mimic brain-like memory and processing capabilities.

Real-World Applications

Beyond virtual experiences, improved ASS powered by these advanced nanoparticles have real-world benefits. Electronic noses and tongues already help detect diseases or assess food quality. Haptic interfaces, which mimic the sense of touch, offer realistic tactile feedback in VR environments. Current devices, though, tend to be bulky, heavy, and uncomfortable for prolonged use.

Nanoparticles produced through LAL enable ASS to become flexible and wearable without sacrificing accuracy. These lighter, flexible devices promise more comfortable, long-term use.

Furthermore, because LAL avoids complicated chemical processes, it reduces costs, potentially accelerating the adoption of these advanced systems in everyday technologies.

Challenges and Future Directions

Despite the many advantages, LAL technology faces hurdles. Researchers must ensure nanoparticles remain stable over time without adding contaminants or surfactants. Integrating the LAL process into existing large-scale manufacturing pipelines also requires further refinement.

Future research will focus on continuous nanoparticle production systems, real-time monitoring for better quality control, and developing practical devices that leverage the full potential of these nanoparticles. Overcoming these challenges will make LAL-produced nanoparticles a foundational technology for next-generation sensory systems.

As extended reality becomes increasingly embedded in daily life, cleaner and more efficient nanoparticle production methods like LAL promise a new era of interactive and immersive experiences.

By closely imitating human senses, these enhanced artificial sensory systems may soon change how you see, feel, and engage with the digital world.

Research findings are available online in the International Journal of Extreme Manufacturing.

Note: The article above provided above by The Brighter Side of News.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.